ABS resin is a very popular type of plastic to manufacture a variety of products. Think of a plastic that is tough, stretchable and moldable to almost any form! To turn this sky blue plastic into a really something special, it is mixed in by three different parts.

These three parts have high-falutin’ science names: acrylonitrile, butadiene and styrene. Mixing them in various proportions allows the plastic to exhibit diverse properties. Some mixes make the plastic more resistant to heat, other mixes make it stronger when bumped or dropped.

ABS resin is responsible for many items we see and use every day. Specifically, that’s where you can find it in your computer keyboard, some of your toys, and parts of household machines. This plastic, which can easily be formed in a variety of shapes and sizes, is a favorite among car makers.

ABS resin is super tough, and this is one of the coolest things about it. It is a plastic that does not easily shatter when you drop a toy made from it. That makes it awesome for things that you need to be strong and to last for a long time. It also resists damage from other liquids, making it really versatile.

But ABS resin isn't perfect. If it heats up too much, it could start to warp or break. Scientists and makers are continuously developing ways to improve it. (We need to develop some use for this plastic that doesn’t pollute the planet and ruin the environment.)

ABS resin was used to create some really amazing things. Did you know it can be used for making 3D printed objects? But with this unique plastic, machines can now make nearly anything. Some makers even use it to print special body parts to assist people who need them.

Makers who choose ABS resin like it because it allows them to tweak compositions to achieve exactly what they want to make. It’s a sort of magic plastic that can be made soft, hard, flexible, or whatever else it needs to be given the purpose it serves.

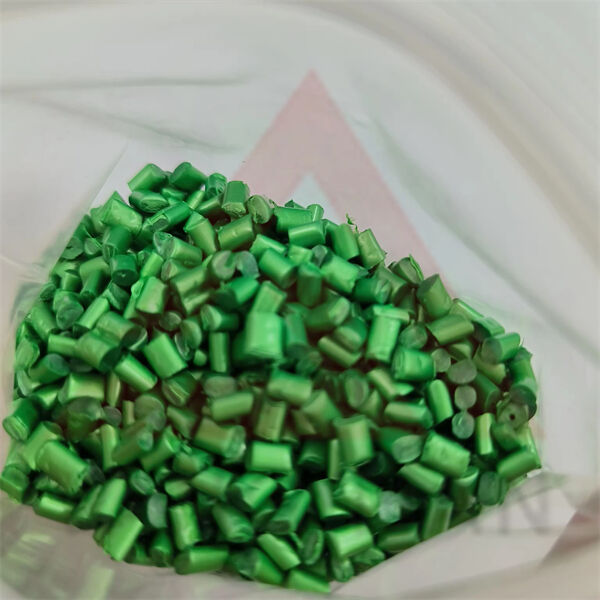

Environmental Masterbatch A small centered business on technology, incorporates research and development, production and sales along with after-sales services. It produces that weigh 5000 tons each, on 15 production lines month. Our sales network spans more than 60 countries and regions that cover different elements of China, Europe and America as well as the Middle East, Southeast Asia, Africa, India, and lots of other nations.

Main products: Black/White abs resinDesiccant Masterbtch master batch to filler with CaCO3/Na2SO4/BaSO4 Flame Retardant master batch, Brightener master batch along with other useful master. We offer custom-designed solutions based on the user's needs and provide free samples try. An order after satisfactory testing, place.

Utilizing the most advanced equipment and technology, including automated machines, standardized procedures, and abs resin designed by scientists guarantees the production of high-quality products. The product has received RoHS certification for environmental protection, FDA certification, REACH certification and SGS certification

Our Environmental Masterbatchis specialized in the theory "Survive through Quality, Build with Credibility" We specialize in providing clients with a complete remedy plastics as well as fast, efficient, and safer logistics solutions. We have a 24/7 hotline for after-sales support and solutions.