Another prevalent problem encountered during the manufacture of plastic goods may be foam. This will cause defects in the final product and reduce its overall quality. Fortunately, the problem has a simple solution -It is defoaming masterbatch used under the compounding process. This unique additive is integrated into plastics when the plastic parts are manufactured to eliminate any foam. As a highly marketable product the use of defoaming masterbatch can be very beneficial to various other advantages.

The primary function of defoaming masterbatch is to reduce the surface tension as plastics are produced and hence, at this early stage in their manufacture suppress foam creation. The problems such as bubble, shortage of mold filling (pit) and hole on surface were solved by adding masterbatch defoamer to the production process. This solution is especially suitable for the manufacturing of films, pipes and injection-molded products as these are natural victims to foam-related issues. In addition, defoaming masterbatch is suitable for many kinds of plastic substrates such as polyethylene and its copolymers (LLDPE supermicron), Polypropylene(PP) etc.

Defoaming masterbatches could also be well-mixed with other materials and additives to make themselves more effective. The use of defoaming masterbatch is necessary in polyolefins, EVA, PE (including LLDPE/HDPE), PP, PS(POLYSTIRNE)PET.PVC and PU etc because these are "foam generating" polymers. Besides the defoaming masterbatch, we can also use additives such as nucleating agents to enhance performance. Nucleating agents cause the compound to form uniform grains (gomyung-ga) of carbonate and hydroxocarbonate, which are tiny bubbles easier to eliminate from finished product surfaces.

Recent developments in defoaming masterbatch science have made a quick impact on reducing the foam problems efficiently. These innovations range from creating specialty masterbatch to integrations molded for specific applications and custom blends engineered specifically around unique processing needs. A specialty masterbatch is designed to address specific problems encountered in plastic manufacturing, like heat stability, color improvement, UV protection or odor elimination. Alternatively, custom blends are a result of mutual additives combined to form formulas tailored for specific needs in the production process. This personalized touch can maximize the manufacturing process, and improve the quality of end product.

Untreated Defoaming masterbatch:Distributed uniformly in the plastic product mass, by increasing resistance of MN can prevent blowing phenomenon and reduce many pores density. This additive helps in controlling foam related problems and maintains the quality as well consistency of the final output. By incorporating defoaming masterbatch in the plastic production process, businesses can improve efficiency, minimize scrap waste and - therefore- increase their profitability.

In summary, the addition of defoaming masterbatch to plastic production can increase both product quality and stability. When combined with suitable materials and performance additives, this delivers a unique solution that helps businesses get better returns on their investments by offering superior performance so they can maximize productivity. Therefore, to ensure the production of high quality non-foam or foam-challenged plastics, in fact you are advised to use defoaming masterbatch technology!

Environmental Masterbatch is a tech-driven company integrates tech research and developing, production, sales, and help that was after-sales. It hosts 15 production lines that produce 5000 tons of different every month. Our sales network covers most than 60 countries, which includes China, Europe, America, Southeast Asia and Africa.

The Environmental Masterbatchis dedicated to the principle of service "Survive with quality, establish with full confidence". Our company is expert in providing customers integrated synthetic functional options along side speedy, safe and convenient logistic services. We offer a 24-hour hotline support after sales and solutions.

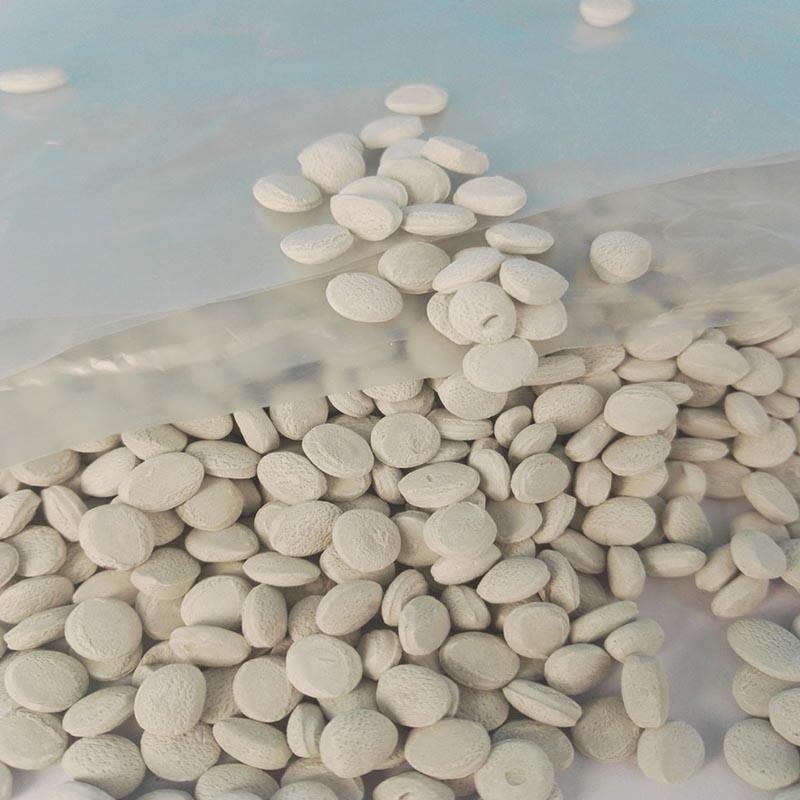

Main products: defoaming masterbatchin white, black and white Desiccant master batch CaCO3/Na2SO4/BaSO master batch; Flame Retardant Master batch; Brightener Master batch along with other Master batches with functionalities. We can provide custom solutions on customer specifications and can provide examples to use. Place an order after conducting tests.

defoaming masterbatch design that is scientific and rational Automated machine production advanced testing equipment standardized operation for each process, guarantee to supply high-quality products. The product is certified by FDA, SGS, RoHS and REACH.