DESICCANT MASTER BATHCES - A SOLUTION TO MOISTURE PROBLEMS IN PLASTICS INDUSTRY...

Advances in plastic compounds that they are using, one of them launch the product through which Masterbatches from desiccant has introduced, and it is revolutionary Innovation when we talk about Desiccant master batches because now you will not problem anymore moisture absorption for long run. These engineered materials combine polymer carriers with powerful desiccants to allow manufacturers a way to protect components from moisture induced failurecdfemoisture-related defects in their products. In addition to increasing the quality of products, many companies can reap numerous benefits and help meet sustainability objectives by incorporating desiccant master batches into their manufacturing processes as this technology is an outstanding way to become involved with reduced costing concerning sustainability practices where both parties will agree on sophisticated science.

Most of the issues occurring in plastic processing are related to moisture problems, including bubbles on product surfaces or inside, surface defects and weakening structures. Desiccant master batches work as an in-situ drying agent absorbing and entrapping moisture thus limiting damages caused due to it. It ensures not only defect removals but also consistent product performance in different environments and conditions. Desiccant master batches are said to be in a range of industries such as automotive, electronics and packaging where precision & reliability is paramount since they help maintain desired high quality standards.

In addition to improving product quality, desiccant master batches provide various benefits that smoothen the production process. Of particular importance is the reduction in pre-drying of plastics, which saves energy and time while reducing material handling — significant steps toward increasing productivity and throughput. They also help to produce thinner wall designs with no loss in strength while supporting lightweighting measures that are needed for cost and environmental benefits. Reduced scrap rates and rework lead to a higher profitability reducing making desiccant master batches worthwhile for manufacturers.

Green desiccant master batches are a game-changer in this era of sustainable business. These eco formulations typically utilize biodegradable or recycled content, helping recently determine the carbon footprint of multiple plastic products while still delivering top performance. In addition, these master batches reflect circular economy principles by enabling the use of more moisture-laden recycled content This plays a part in cleaning up of the entire production process, by matching with global sustainability goals and also enhance brand image for eco-friendly targeted audience.

Desiccant master batch technology is based on the accurate use of desiccants and polymer carriers mixing_DONE Most desiccants, such as molecular sieves or highly effective absorbents are extremely hygroscopic. It is easily absorbed therewith and it binds the residual moisture during processing or after storage. It all comes dwon to the sustained-release technology that would include optimum activity of teh desiccant throughout its life without altering properties of endemic polymer. The key to this fine balance of functionality and compatibility lies in extensive detail investigations together with intensive research & development (R&D) that yields tailor-made master batches for different polymer systems or applications.

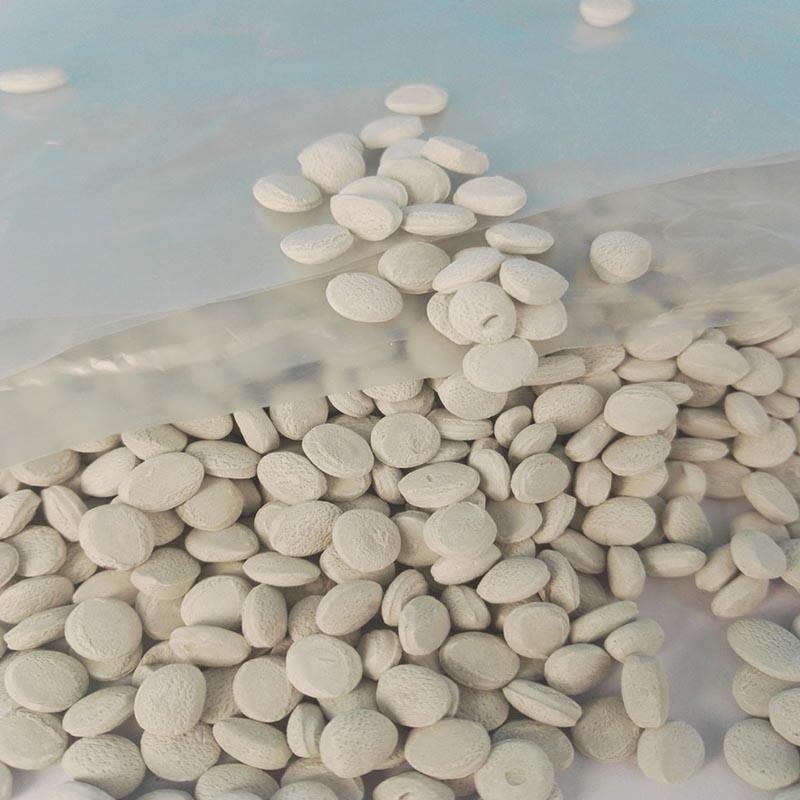

Main products: desiccant master batchin white, black colored and white; desiccant master batch; CaCO3/Na2SO4/BaSO4/Filler master batch Flame Retardant Master batch; Brightener Master batch and differing other Master functional batches. You can expect personalized solutions based on the consumer's specifications and will provide samples to test. After satisfactory testing, make an order.

The use of advanced technology and equipment, such as automated machines, standardized procedures, and desiccant master batch designed by scientists assures the supply of top-quality products. The product is certified RoHS environmental certification, FDA certification, REACH certification, and SGS certification

The Environmental Masterbatchis focused on the principle of "Survive with Quality, Develop with Credibility". We concentrate on providing customers with integrated solutions for plastic functional needs speedy, efficient and logistics safe possibilities. We provide clients with a 24 hour after-sales support as well as incorporate solutions.

Environmental Masterbatch an according business to technology, incorporates analysis and development manufacturing and sales as well providing after-sales support. It generates of 5000 tonnes each using 15 production lines month. Our deals network spans most than 60 countries, including China, Europe, America, Southeast Asia plus Africa.