One of the most fascinating technologies in plastic manufacturing is masterbatch. In particular, the development of functional masterbatch is transforming applications for plastics. Functional masterbatch: a kind of special material that could be added into plastic to give it with functional characteristics such as color, UV resistance and fire proof. Secure serviceability in addition to numerous functionalities could possibly be understood using functional masterbatch technology by which, producers can produce plastics of supreme quality and prepared as per essential according with their requirementnces.

This is projected to bode well for the high-performance plastics market, especially on account of a broader acceptance across various end-use industries including nylon masterbatch applications. With growing demand for innovative, high-quality plastics across a wide range of market sectors functional masterbatch is set to take on an even greater role in driving the advance of plastic production. One significant gas assisted molding technology, that provides for enhanced productivity as well its versatility and higher quality of parts.

Functional masterbatch technology offers manufacturers a host of benefits, such as standardizing color management, UV protection and fire retardation. When employing functional masterbatch, makers can easily produce plastics that meet certain requirements and exceed customer needs in a wide array of apps. Whether they manufacture consumer goods, industrial machinery or medical instruments functional masterbatch allows manufactures to modify the properties of their materials and improve performance.

Functional masterbatch technology offers a significant advantage as it helps in customizing the properties of plastic to match exact needs. For example, manufacturers can improve the mechanical characteristics of plastic (its strength, elasticity and flexibility) by loading it with functional additives. They can improve and control the visual qualities of plastics, like transparency or colour range as well as more surface finish options Functional masterbatch technology also enables manufacturers to construct plastics that provide the best in class performance for their customer base across a range of applications.

Now, its influence is poised to grow over the coming years as functional masterbatch technology changes our plastic manufacturing landscape. Such as in the automotive industry, functional masterbatch is being used to improve durability and cosmetic requirement of interior & exterior parts. Functional Masterbatch on Packaging: One of the offers from functional masterbach technology is to improve barrier properties, protecting plastic for moisture, oxygen and other contaminants. In the medical industry, functional masterbatch is playing a role in producing plastics that can withstand sterilization procedures and meet very strict regulatory requirements.

To sum up, functional masterbatches technology is revolutionizing in the world of plastic production. This ability to improve plastic properties and tailor them towards certain requirements is promoting innovation at an industry-scale to categories such as automotive, packaging degines through medical devices etc. What this means for the future of high-performance plastics and where it seems likely that these polymers are headed is towards an exciting era year ahead, both behind-the-scenes at materials processing facilities as well on retail shelves.

Our Environmental Masterbatchis committed to the tenet "Survive by Quality, Grow with Credibility" We specialize in providing customers with a complete remedy plastics and quick, easy, plus secure logistics services. You can expect an available hotline one day each and every day to include after-sales assistance possibilities.

Environmental Masterbatch is an ongoing company which try tech-driven integrates research plus development in technology, production, sales, along with after-sales service. It produces of 5000 tonnes each, on 15 production lines thirty days. Our selling network spans a lot more than 60 countries, like China, Europe, America, Southeast Asia and Africa.

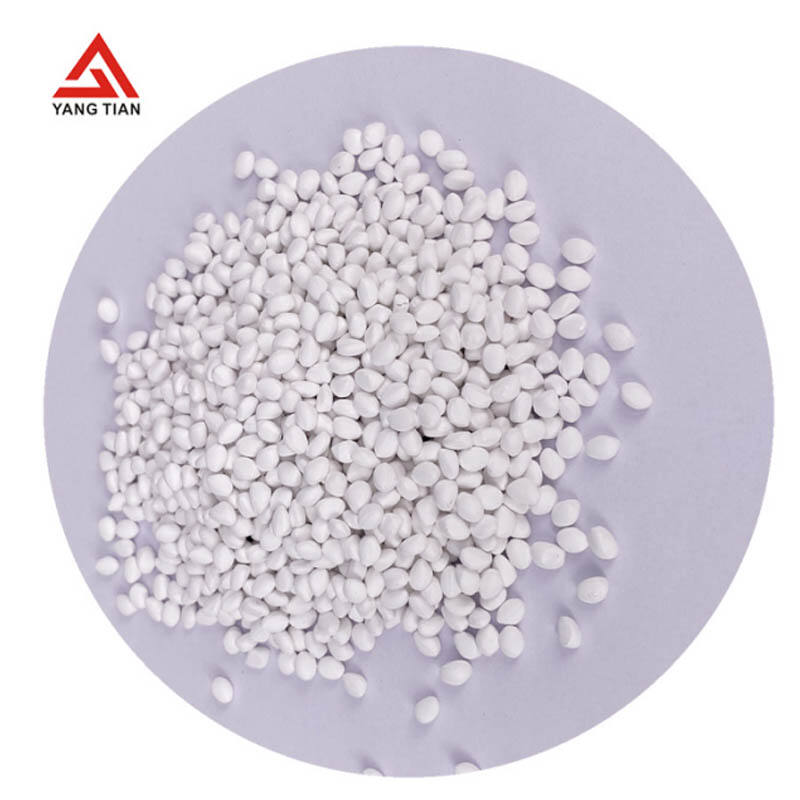

funtional plastic masterbatch design that is scientific and rational Automated machine production advanced testing equipment standardized operation for each process, guarantee to supply high-quality products. The product is certified by FDA, SGS, RoHS and REACH.

Principal products: white/black/color funtional plastic masterbatchDesiccant master batch; CaCO3/Na2SO4/BaSO master batch Flame Retardant Master batch; Brightener Master batch and more Master batches for functional purposes. In line with the needs of customers We can offer custom-designed solutions free samples test. Spot an order after conducting tests.