It is a material widely used in the manufacture of individual parts within sectors as wide ranging as plastic injection molding. Some of the areas you will most commonly find it in include packaging, construction applications and automotive. Yet the use of plastic is only one such action. Manufacturers will then have to make further adjustments on these properties in order for those electromagnetic wave-interference prevention strategies are suitable enough with the requirements of their product. The master batch additives make it possible to do this

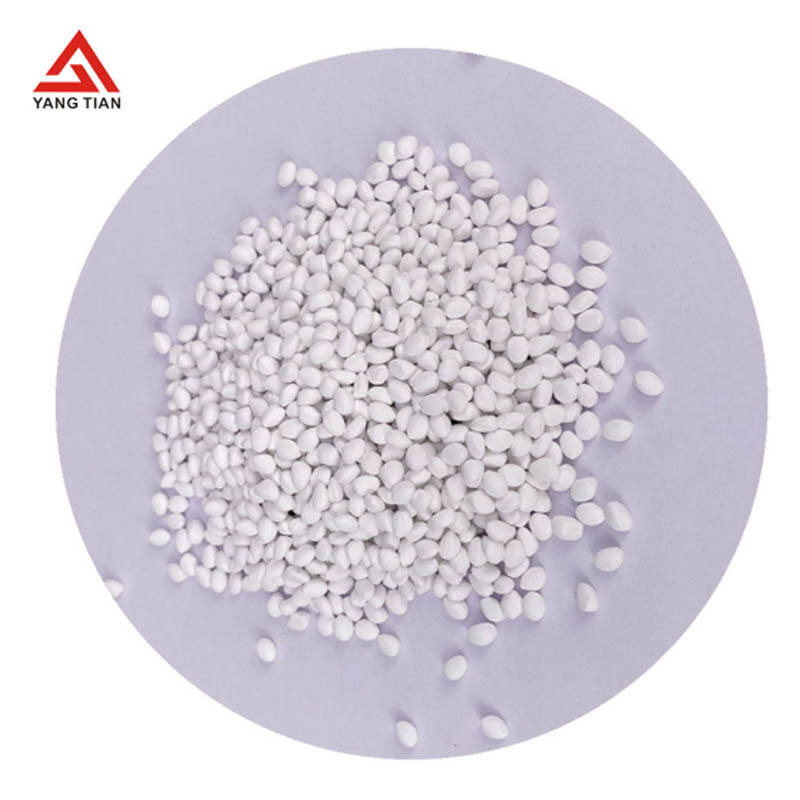

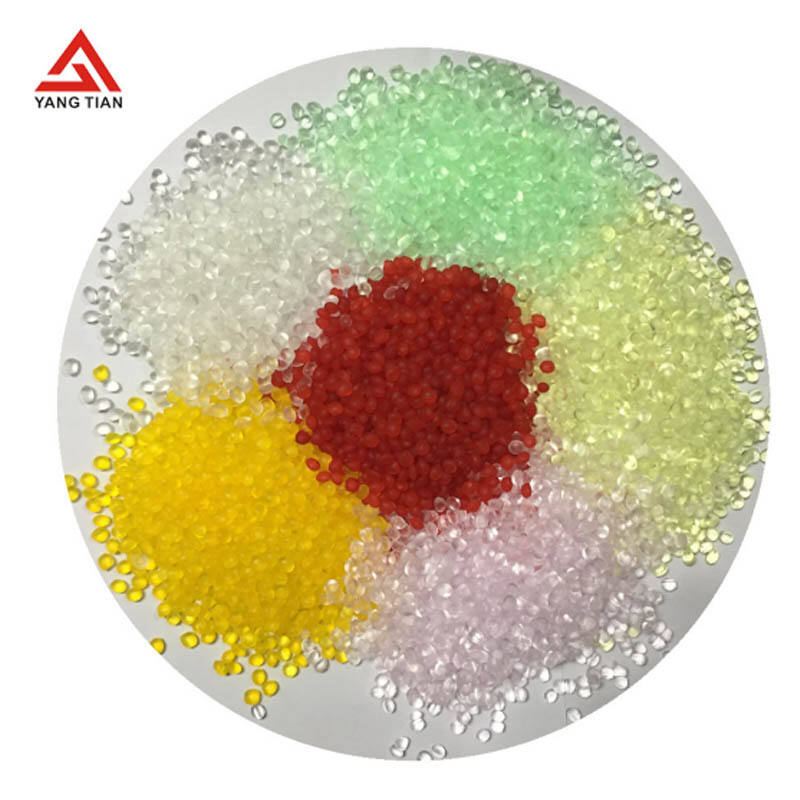

Masterbatch - Adds some of the additional chemicals to unreacted plastic resin which helps in giving desired properties. Assign others without the use of pre mixing for production instead by common additives these performance enhancers can be colorants, UV stabilizers and flame retardant additives.

There are quite few advantages of master batch additives and needless to mention that is the rationale for its wide usage within the plastic processing industry. This can help color orders - a major win for mass production lines needing to hit just the right hue. Especially helpful in industries that require a brand pack with color specifics. Secondarily, they decrease the likelihood of either over/under dosing an additive that improves quality and performance in a plastic item. Gravimetric doser additives master batch and increase waste output in manufacturing,there is always a risk of contamination, last but not least.

So master batch additives are changing the way plastics are made, upping our abilities to shape plastic properties according to their applications. For instance, plastic products in direct sunlight might be colored with UV stabilizers to make sure that the material does not stop working under inappropriate exposure. Plastic can be filled with flame retardants making a plastic even more fire resistant so that it becomes an ideal solution in many branches. In health-related applications these materials can be combined with the addition of antibacterial additives in order to increase their compliance.

Efficiency and Cost Savings in the Plastics Industry: Master Batch Technology

Likewise, master batch technology can generate similar plastic production efficiency and cost savings. Masterbatch additives also save you costs because you no longer have to order multiple additives in different packaging sizes for use. By having faster serviceable completion time and reducing the labor associated with mixing in additives, this will decrease both production times as well as turnaround time.

The master batch additives provide assists in the enhancement of plastic properties;

Consumers want that their selected color is matching all of the tributes which are given in their choice and this can be achieved by using MASTER BATCHTechnology.

So, the longer life of plastic is crude with all types UV stabilization are used in it to protect material from degradation.

Flame Retardation -Burn Conductivity: Because of the way that fire retardant aggregated create to plastic products through a chain, melt out undeveloped segment outside concerning dangerous situation.

In addition, the inclusion of silver ions as an additive will constitute a nobilitation for plastic products and even more bactericidal properties to be produced from them; therefore they can provide better defense against various diseases mainly when applied in different components of medical equipment.

To sum up, master batch technology is how the plastic industry simplifies manufacturing and enhances properties of substances. With the help of master batch additives, different types of plastic can be produced according to special measures, for example in color modes or with UV protection, flame retardance and higher hygiene. This technology allows the manufacturers in increasing higher productivity & lowering costs faster and simultaneously provides premium quality products. Everyone -- literally everyone -- who has an opinion on the issue will tell you that we must keep using it to grow and prosper in the plastics industry.

The use of the latest equipment and technology, including automated machines, standardized procedures, and master batch in plastic that are scientifically designed assures the supply of top-quality products. The product has passed RoHS environmental certification, FDA certification, REACH certification, and SGS certification

The Environmental Masterbatchis dedicated to the principle of service "Survive with quality, establish with full confidence". Our company is expert in providing customers integrated synthetic functional options along side speedy, safe and convenient logistic services. We offer a 24-hour hotline support after sales and solutions.

Environmental Masterbatch is an ongoing company based on technology that integrates technology research and development, production, sales, as well since after-sales solution. It hosts 15 production lines that produce 5000 a lot of various per month. Our sales and marketing network spans over 60 countries, which include Asia, Europe, America, Southeast Asia and Africa.

Principal products: white/black/color master batch in plasticDesiccant master batch; CaCO3/Na2SO4/BaSO master batch Flame Retardant Master batch; Brightener Master batch and more Master batches for functional purposes. In line with the needs of customers We can offer custom-designed solutions free samples test. Spot an order after conducting tests.