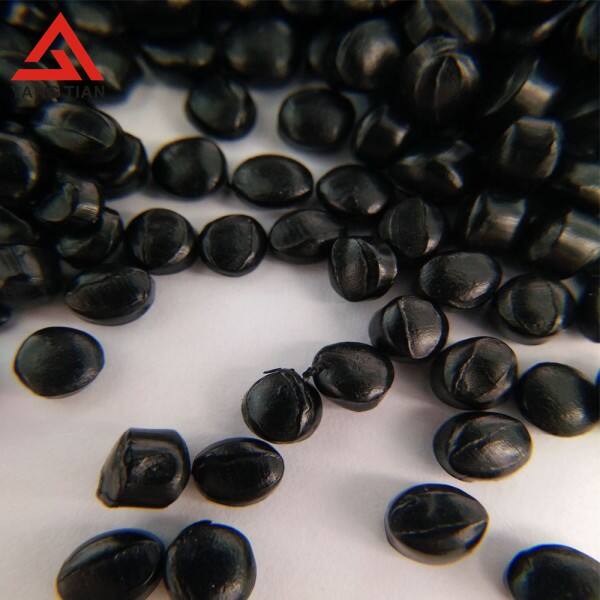

Looking for a real way to add color, functionality, or both to their plastic products? If so, masterbatch manufacturing may be the answer you may be seeking. Masterbatch are a concentrated mixture of and/or additives being added to raw plastic to improve its properties, like extrusion molding masterbatch created by Environmental Masterbatch.

Masterbatch manufacturing has advantages that are several more practices of coloring or modifying plastic, same with the injection molding masterbatch innovated by Environmental Masterbatch. First of all, it is cost-effective since it allow for the use of lower-grade materials which can be raw. Additionally, masterbatch provide consistent and uniform coloring throughout the synthetic product. It is also more green as the level of vinyl waste generated during the manufacturing process is significantly reduced.

For example, a UV masterbatch can feel included to enhance the product's resistance to ultraviolet light, or an antimicrobial masterbatch be added to makes the product more resistant to bacteria as well as other microorganisms. This versatility creates the manufacturing of masterbatch highly appealing, and it open up a variety of new applications for plastic items.

Innovation have been a driving forces the development of masterbatch manufacturing, and new technology are continuously being developed to improve and expand upon the process, just like the brown masterbatch built by Environmental Masterbatch. Recently, the development of a liquid masterbatch gained popularity due to its ability to produces more complicated and unique color colors. These liquid masterbatches can also be easily mixed with other additives, permitting greater flexibility into the final item design.

The security of masterbatch manufacturing processes is of utmost importance to manufacturers, manufacturers, and consumers alike, identical to blowing film masterbatch supplied by Environmental Masterbatch. Masterbatch manufacturing is generally considered to be a safe process as it uses less raw material drastically reduces the quantity of waste produced. Its also a safer ways to include pigments and additives to products that are plastic it eliminates the significance of additives to directly be added to the vinyl before manufacturing.

Additionally, suppliers of masterbatch are needed to comply with safety regulations and standards set by the national government and agencies that are related. This guarantees that the masterbatch they produce is safe and reliable for use in various applications.

The specified amount is added to the raw plastic material during the manufacturing procedure to use masterbatch, similar to the pink masterbatch developed by Environmental Masterbatch. The added masterbatch is then mixed evenly with the raw plastic to create an uniform color or incorporate the desired functionality. It was important to utilize the recommended dosage which varies from a type or kind of masterbatch to another, to attain the desired outcome.

Masterbatch can be included up to a variety of synthetic products, including packaging components, automotive components, electrical appliances, and even toys. By using the masterbatch that was appropriate manufacturers can enhance the product's quality, improve its aesthetic appearance, and add unique features.

Main products: masterbatch manufacturing processin white, black and white Desiccant master batch CaCO3/Na2SO4/BaSO master batch; Flame Retardant Master batch; Brightener Master batch along with other Master batches with functionalities. We can provide custom solutions on customer specifications and can provide examples to use. Place an order after conducting tests.

Environmental Masterbatch is an ongoing company which try tech-driven integrates research plus development in technology, production, sales, along with after-sales service. It produces of 5000 tonnes each, on 15 production lines thirty days. Our selling network spans a lot more than 60 countries, like China, Europe, America, Southeast Asia and Africa.

The Environmental Masterbatchadheres towards the principles of "Survive with quality, create with confidence". We're an expert in providing customers integrated synthetic practical possibilities, as well since speedy, safe and convenient services being logistic. Our users can avail a 24 hours after-sales support and also provide solutions.

masterbatch manufacturing process design that is scientific and rational Automated machine production advanced testing equipment standardized operation for each process, guarantee to supply high-quality products. The product is certified by FDA, SGS, RoHS and REACH.