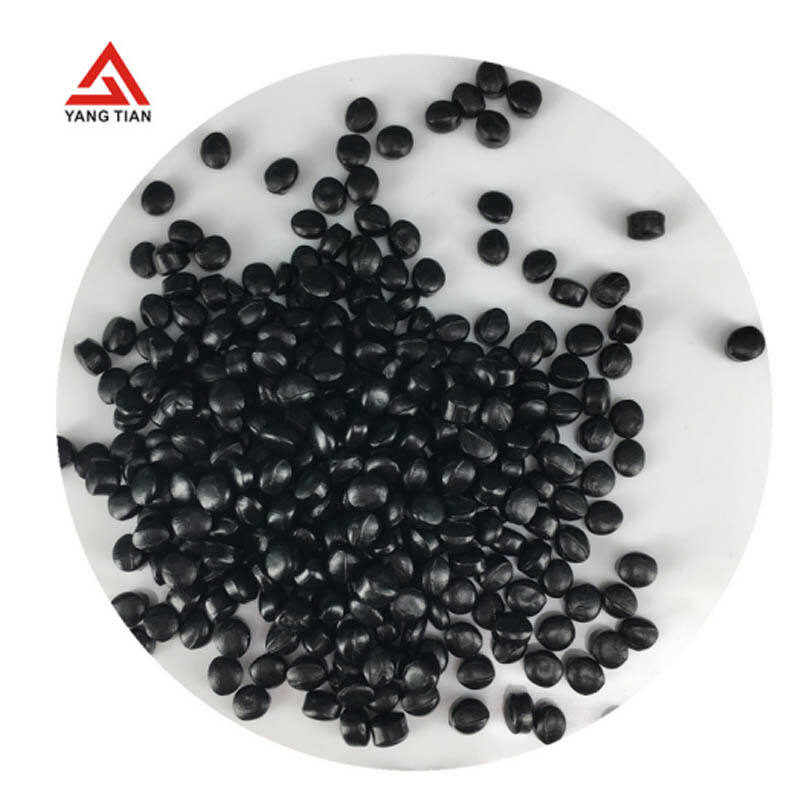

In brief, Oxo Biodegradable Masterbatch is a formula that combines with the raw plastic in about 2-3% during production of what replaces all finished product.

Oxo biodegradable masterbatch is a unique type of additive which can be added together with plastic items to assist them disintegrate more rapidly. The masterbatch contains minute particles with an additive which quickens the plastic breakdown when in contact with oxygen and light. This degradation process, i. e., oxidation, helps the plastic to break down into smaller pieces in a lesser presence of time when compared with normal plastics.

The process of biodegradation includes plastic being decomposed by microorganisms into elements like carbon dioxide, water and biomass. Oxo biodegradable masterbatch simply speeds up the process by crumbling down larger pieces of plastic into smaller fragments that are more easily digested by these organisms. Which, in turn makes it a tidy way of halving the quantity of plastic waste that ends up on landfill and within the environment.

Sustainable packaging is currently in the drainage due to oxo biodegradable masterbatch. The most important one, especially in the modern age where plastic waste has such a huge negative effect on our environment. Plastics that require centuries to decompose end up being long-lasting pollution of our environment even when they've only been used once. Oxo biodegradable masterbatch has the power of making a considerable reduction inthe amount of plastic waste that reaches our oceans and natural environments.

Compliance with environmental protection laws and standards -Oxo biodegradable masterbatch is available for a critical reason. Countries and regions are launching rules to restrict the use of plastic packaging and promote biodegradable, degradable products. Switching to oxo biodegradable masterbatch can satisfy these demands and enhance their status as environmentally responsible organisations.

The use of oxo biodegradable masterbatch in plastic products has several advantages. It first of all speeds up the biodegradation process that environment takes with plastic items, Second, it extends the lifespan and quality of the product by protecting them from UV rays and oxidation. This in turn extends the life of a product, reducing repair or replacement.

Using oxo biodegradable masterbatch in companies will result more customer loyalty and better brand reputation. Consumers are getting woke to the fact that plastic waste is bad for Mother Earth and demanding more ecologically-friendly options. One company can stand out from the competitors and bring new customers in if they sell biodegradable / eco-friendly products.

Adding oxo biodegradable masterbatch to your manufacturing method is an easy-going process. The masterbatch is normally dosed to the plastic resin, typically within a range of around 1-3% by weight. Masterbatch dispersion in the plastic, so as to make it able for biodegradation throughout.FormBorderStyleoptimization of available processes valid for this particular kind (see previous point.).

Manufacturers can choose to partner with suppliers that offer custom solutions designed for the product, application and processing conditions. This allows them to run at their best and work with current equipment and processes.

There are many oxo biodegradable masterbatch options on the market, each offering different qualities and performance attributes. Some examples include:

The UV Stabilized Oxo Biodegradable Masterbatch: Provides sufficient protection from the sun and is used mostly for outdoor applications.

In the case of Food-grade Oxo Biodegradable Masterbatch: It is specially practice in food packaging material, complies with rigorous food protection rules and regulations do not impact on help or wish scenery.

OXO Biodegradable Colored MasterbatchThis type of master batch enables the production od bio-degradoble colored plastic parts in case that colour is important.

In conclusion, oxo biodegradable masterbatch is a versatile and practical means to plastic waste reduction. This will assist manufacturers in improving their sustainability credentials, meeting regulatory requirements and reducing the environmental footprint of plastic products. With a variety of solutions and tailor-made options, the transition to oxo biodegradable masterbatch is now more accessible than ever before.

Main products: Black/White oxo biodegradable masterbatchDesiccant Masterbtch master batch of filler caCO3/Na2SO4/BaSO4 master Flame Retardant master batch, Brightener master batch and other useful master. We provide custom-designed solutions in relation to the buyer's specifications and supply free samples try. Order after testing.

The Environmental Masterbatchis invested in the ongoing service principle of "Survive with Quality, Develop with Credibility". We offer customers and a solution which was complete plastic and quick, effortless, and safe logistics services. Day we offering an available hotline 24 hours the to guide after-sales and provide solutions.

Environmental Masterbatch is an ongoing company which try tech-driven integrates research plus development in technology, production, sales, along with after-sales service. It produces of 5000 tonnes each, on 15 production lines thirty days. Our selling network spans a lot more than 60 countries, like China, Europe, America, Southeast Asia and Africa.

The use of advanced technology and equipment, such as automated machines, standardized procedures, and oxo biodegradable masterbatch designed by scientists assures the supply of top-quality products. The product is certified RoHS environmental certification, FDA certification, REACH certification, and SGS certification