PP/HDPE/LDPE PE MASTERBATCH is a unique chemical ingredient which used to improve the properties of plastic products. Used in plastics: This unique material is Izodimidine showing imperativeness when it comes to plastic production; increasing the durability and long-lasting capacity of plastics products. PE filler masterbatch is composed of small, lightweight particles that are able to easily integrate with plastic in order to increase its life and enhance the physical properties once it has been completed during production.

The use of PE filler masterbatch is very beneficial in plastic production. Most importantly, it strengthens the strength of plastic products so that all suitable goods made with this product are tougher and far more resistant to harm or wear over time. Another main advantage is that the weight of plastic goods can be curtailed after incorporating PE filler masterbatch. Thanks to this, the plastic structure contains more space within its components and filler particles weight is lowered (this meaning of decrease consists in shrinking the class size). The light duty nature of this feature is important for lightweight objects like toys and consumer electronics.

Advancements in PE Filler Masterbatch Technology as demand increases for stronger and more durable plastic products In recent years, pioneering innovations are being released in the field of filler masterbatch technology which allows manufacturers to produce more robust plastic articles ever produced. For an example of more recent progress in PE filler masterbatch improvement, how to combine them with nanotechnology. This trailblazing method of mucking about with tiny particles -measured in nanometers- was developed to serve as a replacement for much more intrusive, nanoparticle-altering surgical interventions. Using nanotechnology, plastic manufacturers have managed to produce filler particles that are much tinier and lighter than traditional varieties which allow for the development of incredibly robust yet lightweight plastics.

Now, safety is always the priority when one speak of chemical substances and PE filler masterbatch does not make an exception. Nevertheless, the way in which this PE filler masterbatch is utilized has been severely regulated by a total of strict safety protocols that make it entirely safe to be used on virtually all plastic manufacturing processes. Consequently, the U.S. Environmental Protection Agency (EPA) and European Chemicals Agency have some decree for oversight of PE filler masterbatch application. These regulatory agencies require stringent safety assessments of chemical substances before they can be used commercially.

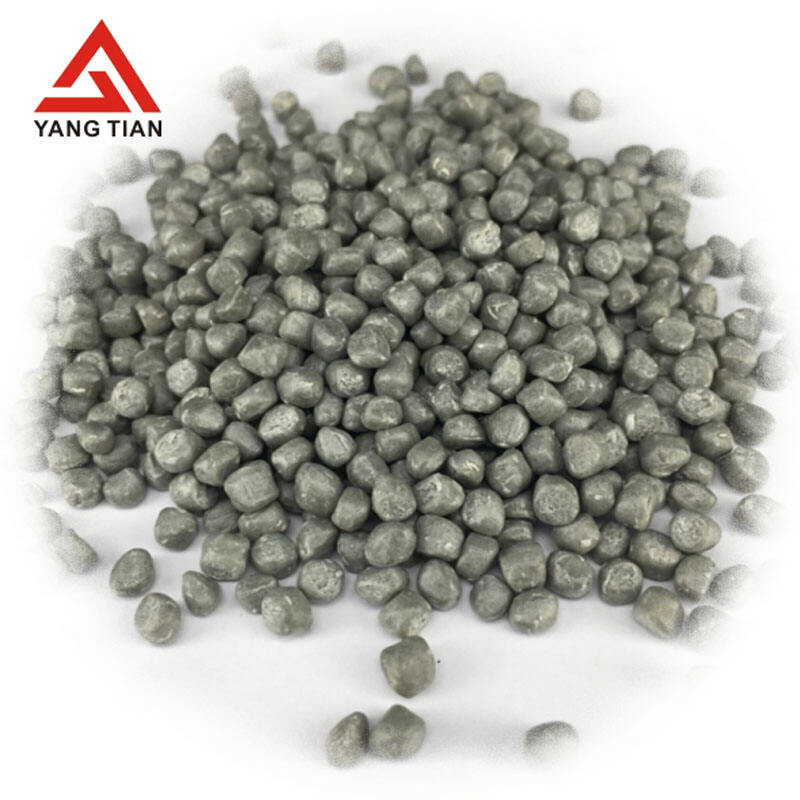

The process of introducing PE filler masterbatch into plastic manufacturing procedures has long been a hassle-free action. It is delivered in pellet form for direct addition to the plastic during production as a masterbatch. The amount of masterbatch needed changes as for each type of plastic and the results you are trying to make. The masterbatch must also be used to its best advantage with the manufacturer, taking into account both process viscosity and melting point of the plastic materials.

Quality and Service in PE Filler Masterbatch

The quality of PE filler masterbatch plays an imperative role for any manufacturer that uses this ingredient to produce some or the other kind plastic goods. Trusted vendors of PE filler masterbatch provide top-notch products which have been tested for safety and efficiency. Excellent customer service is also crucial for customers to understand the correct masterbatch needed for their production requirement and help them with technical support. Top masterbatch suppliers must offer complete technical support and consultancy to help their customers uniquely efficiently.

Main products: Black/White pe filler masterbatchDesiccant Masterbtch master batch of filler caCO3/Na2SO4/BaSO4 master Flame Retardant master batch, Brightener master batch and other useful master. We provide custom-designed solutions in relation to the buyer's specifications and supply free samples try. Order after testing.

Scientific and reasonable pe filler masterbatch design, automated machine production modern testing equipment, standard operation for every process and guarantee the supply of high-quality products. The product has passed RoHS environmental certification, FDA certification, REACH certification and SGS certification

Environmental Masterbatch an according business to technology, incorporates analysis and development manufacturing and sales as well providing after-sales support. It generates of 5000 tonnes each using 15 production lines month. Our deals network spans most than 60 countries, including China, Europe, America, Southeast Asia plus Africa.

Our Environmental Masterbatchis targeted on the concept "Survive through Quality, build and Credibility" We focus on providing customers with integrated plastic functional solutions quick, easy, and logistics secure services. We have a 24/7 hotline for after-sales support and solutions.