HomeBusiness Business OpportunitiesThe Importance of Using Plastic Black Masterbatch to Improve the Quality of Your Plastics

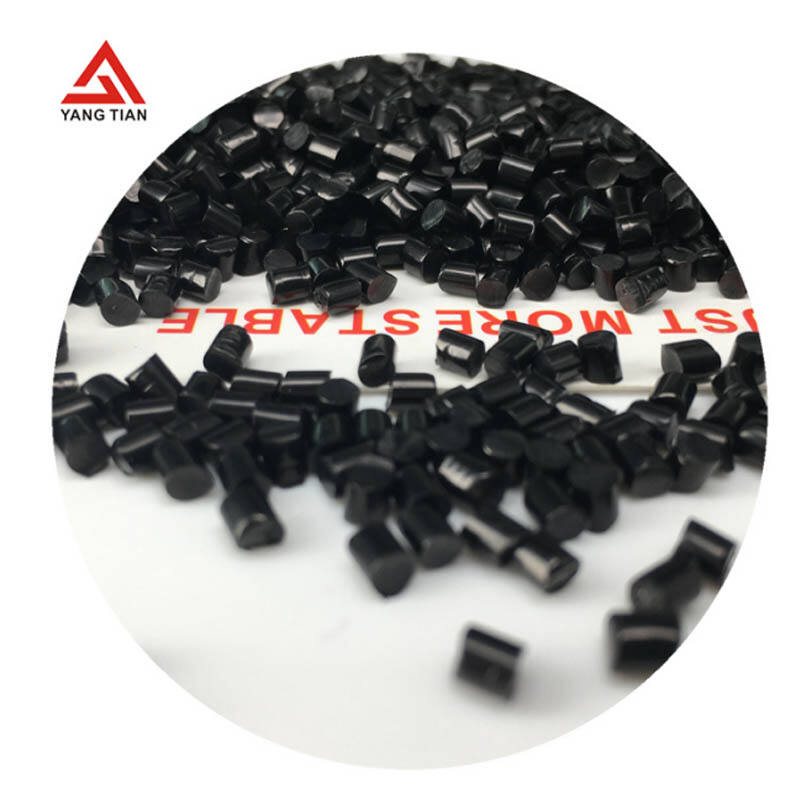

The introduction of plastic black masterbatch in the field of plastics not only increases their appeal but also strengthens a host other items. These are just highly concentrated combo of colors, carriers and additives which give your plastic products not only vibrant color but also help to improve the quality. In addition to just color, black masterbatch become more complex gradually as methords of manufacture improve and the emphasis on sustainability increases. It delivers eco-friendly products, savings on cost and easily adopts to be used in many industries.

One of the reasons it is significant to manufacture this one lies in its properties - more specifically, these tires evenly dispense carbon black; an essential pigment for creating that pure deep-inked-black hue. This ensures the color is consistent, eliminating any possibilities of streaks or randomness that may be present to affect its overall look. Similarly, black masterbatch does more than just color the plastic; it also provides UV protection and anti-static properties while improving material toughness. In one shot processing instances (such as extrusion or injection molding), the user is allowed to simply drop into a discrete batch of their base resin, and get out at any particular mixture in negligible time; ensuing an overall less downtime than comes with either conventional talc PURs solutions.

How to Increase the Deep and Rich Color Using Plastic Black Masterbatch

Getting deep and rich colors in plastics is a combination of art, but mostly science. The choice of carbon black and the ratio in which it is used within the masterbatch are vital to success on this front. Smaller carbon black particles give better lightfastness, that is the depth and brightness of a colour especially when made with reference to an exposed feeling which can develop upon time reducing it. All of a sudden, this practice would be mastered by also knowing how different types of resin take to the masterbatch and exactly the type black tone that will best suit your product in terms of adding value over the natural aesthetic appeal off plastic. It is in this manner that expertise can turn undifferentiated commodities into compelling items which rise up above the pack on store display.

The introduction of ecofriendly plastic black masterbatch solutions has been a game changer in the world we live today where everyone is more conscious about saving our environment. Subscribe The news of the formulation capabilities was unveiled yesterday, and include recycled or bio-based materials that mean less new resources are needed. Certain manufacturers now produce carbon black from post-industrial waste or recycled tires to provide an eco-friendly alternative with no sacrifice in product performance. Our masterbatches not only reduce carbon emissions, but also conform to a circular economy philosophy - making them an ideal solution for ecoconscious consumers and companies committed to sustainability certification.

In today's manufacturing landscape being competitive requires efficiency and cost-effectiveness. The use of plastic black masterbatch will help reduce waste as well as increase output per production run. Their concentrated form results in much lower costs for transportation and storage as opposed to raw pigment powders. The use of masterbatch also should allow fabricators to ditch the separate colorization steps required for things like foamed PVC, making it a more cost-effective process that requires less labor. These are readily integrated with masterbatch dosing systems, which in turn ensures a wide partition of COLORdosers for precise color control, and further shrink packaging residues or low jelly capacity no 5054-76 grease composition obsolete production practices to bootle even more efficiently quality costs required by predecessors.

Plastic black masterbatch, the largest selling among all other variants is used in everything from packaging to automotive, construction to consumer goods. For packaging, it improves aesthetics as well as light protection which in turn extends the shelf life of products. The automotive sector uses it for exterior and interior elements because of its UV resistance, abrasion-resistant properties etc.. In construction materials such as pipes and profiles, it provides strength & weatherability. It is even used in agriculture, with black masterbatch added to mulch films able to regulate soil temperature and prevent weeds growing - which through this improved microclimate enhances the growth of crops. Its versatility is a clear demonstration of its utility as an essential material in many industries.

Main products: plastic black masterbatchin white, black colored and white; desiccant master batch; CaCO3/Na2SO4/BaSO4/Filler master batch Flame Retardant Master batch; Brightener Master batch and differing other Master functional batches. You can expect personalized solutions based on the consumer's specifications and will provide samples to test. After satisfactory testing, make an order.

A rational and scientific plastic black masterbatch design Automated machine production, advanced testing equipment, uniform operation for each step, guarantee to supply high-quality products. The product has been certified by FDA, SGS, RoHS and REACH.

Environmental Masterbatch an according business to technology, incorporates analysis and development manufacturing and sales as well providing after-sales support. It generates of 5000 tonnes each using 15 production lines month. Our deals network spans most than 60 countries, including China, Europe, America, Southeast Asia plus Africa.

The Environmental Masterbatchis focused on the principle of "Survive with Quality, Develop with Credibility". We concentrate on providing customers with integrated solutions for plastic functional needs speedy, efficient and logistics safe possibilities. We provide clients with a 24 hour after-sales support as well as incorporate solutions.