An Innovatory Creation- Plastic Master Batch

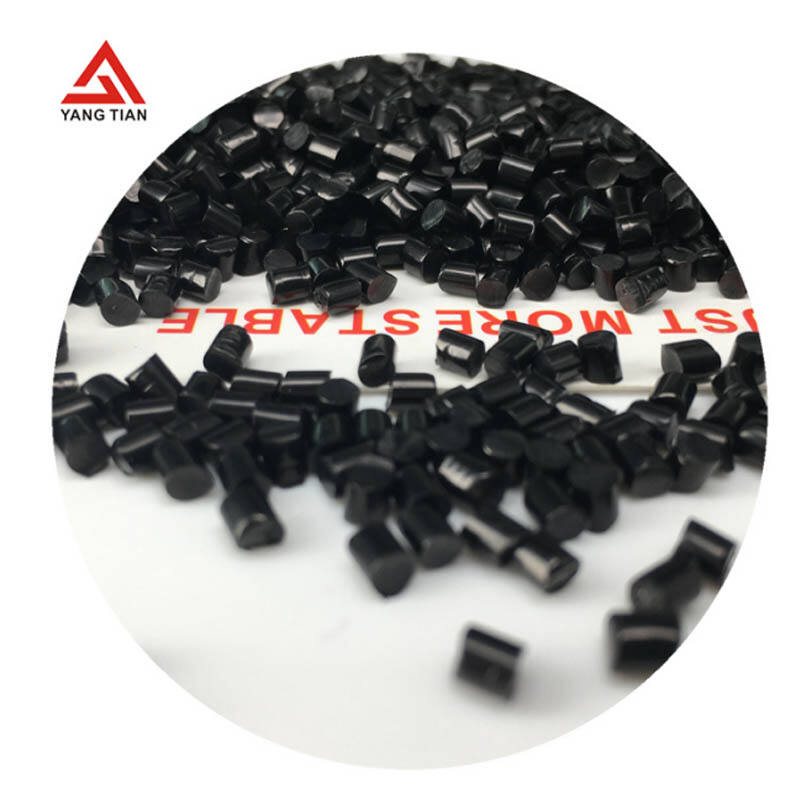

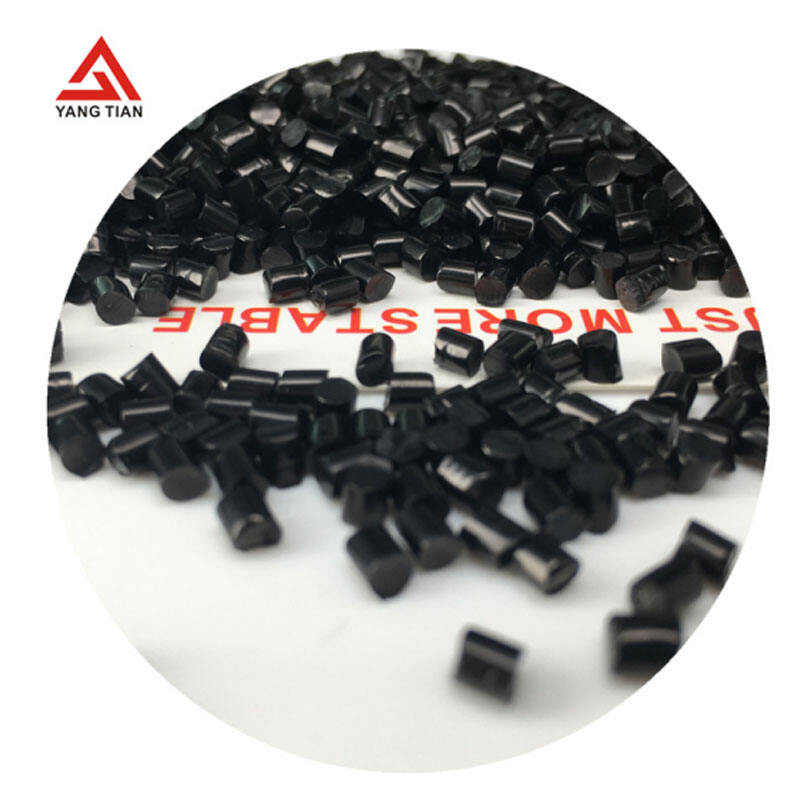

The plastic master batch is a special kind of the additive that developed to improve the color of your resin(plastic). It is a highly pigmented and much denser mix of pigment/dye in carrier resin. All made with this special formula to distribute the color throughout the plastic mixture uniformly, so that it is produced identically on multiple colored Jay-Plast parts.

Benefit of Plastic Master Batch

Master batch coloring of plastic resins is achieved via the use of plastic masterbatches, a technique that comes with numerous advantages. One of the most significant benefits is its accurate color matching and reproducibility, essential in maintaining a consistent brand. Plastic master batch can also help to enhance the aesthetics of manufactured plastic products with colour effects like metallic, or pearlescents. Moreover, it accelerates the production by saving time as compared to manual coloring ways. This time-saving feature is due to the carrier resin which eliminates clumping and ensures an even color dispersion.

A more important plastic innovation in the field- THE PLASTIC MASTER BATCH revamping how color masterbatch were positively mixing: The result is a breakthrough that makes it possible to produce colored plastics at lower cost, with much better efficiency and effectiveness. Plastic masterbatch is regarded as the most efficient method of thermoplastic coloring to utilize, which makes material waste less and reduces errors that may be experienced in hand-coloring processes. Moreover, it gives manufacturers the capacity to manufacture almost any colour imaginable which is helping more and more plastic products are produced for sale in a global market that buyers want not only optically but also visually.

The use of safety measures is essential during the manufacturing process for plastic master batch, and its corresponding coloring solution serves as a safe medium so that users can easily trust it. Made from FDA approved and RoHS compliance raw materials, plastic masterbatches are manufactured keeping safety as the foremost priority. The carrier resins are provided in heat-stabilized polymers suited for high molding temperatures to ensure the colors last over a lifetime. Their dedication and belief in safety means that their customers can rest easy knowing the product they purchased is not going to be an issue down-the-road.

Using plastic master batch is a simple and final process. In order to get the desired colour of that part we need So start with adding proper amount in this plastic material before mixing it. Following the manufacturer's crafted mix ratio is essential in safely assuring you receive the colour desired, time and again. Mix the master batch completely with plastic resin until it becomes a homogeneous mixture The meticulous mixing steps ensure that every colorant molecule is dispersed evenly throughout the system, meaning no speckles or blotches will appear in his finished product.

The color quality of plastic master batch is a key factor in the choice and use of coloring plastics since it can not fundamentally change after application, but affect the overall performance of product. The quality of the master batch is determined by the performance characteristics with respect to pigments, dyes and carrier resin used in its manufacture. It is essential that the plastic resin you plan to color be compatible with the carrier resin if a uniform dispersion of color is desired. Selecting top quality pigments and dyes are crucial when it comes to achieving color consistency & excellent coloration effects. Top-quality master hatch allows manufacturers to maintain manufacturing repeatability and reduces the chances of color fading or even defects in quality.

Environmental Masterbatch is an ongoing company based on technology. It offers research and development, manufacturing sales, as well supplying after-sales support. Month it produces weighing 5000 tonnes every operating 15 production lines. Our sales network spans a lot a lot more than 60 countries and regions that cover diverse regions of China, Europe and America along with the Middle East, Southeast Asia, Africa, India, and plenty of other nations.

The use of advanced technology and equipment, such as automated machines, standardized procedures, and plastic master batch designed by scientists assures the supply of top-quality products. The product is certified RoHS environmental certification, FDA certification, REACH certification, and SGS certification

Main products: plastic master batchin white, black and white Desiccant master batch CaCO3/Na2SO4/BaSO master batch; Flame Retardant Master batch; Brightener Master batch along with other Master batches with functionalities. We can provide custom solutions on customer specifications and can provide examples to use. Place an order after conducting tests.

The Environmental Masterbatchis dedicated to the principle of service "Survive with quality, establish with full confidence". Our company is expert in providing customers integrated synthetic functional options along side speedy, safe and convenient logistic services. We offer a 24-hour hotline support after sales and solutions.