PP Filler Masterbatch is an exceptional product which has proven to be extremely beneficial in increasing the strength and endurance of plastic articles. It protects from UV rays, aging, and static electricity too. If we incorporate PP Filler Masterbatch during production process that is used for Polypropylene flame retardant, almost every material property could be simultaneously improved to ensure consistency and increase the quality of plastic products.

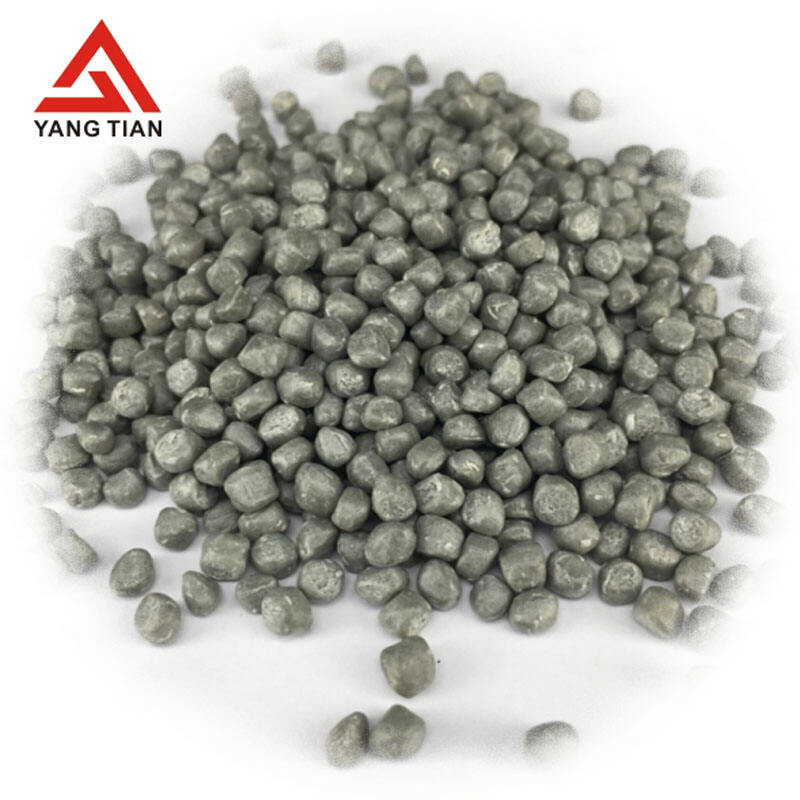

PP Filler Masterbatch: Just Take a Look

It is a type of PP Filler Masterbatch produced, which continuously improves its properties. The manufacturers can produce developed filler masterbatches efficiently that always stay ahead of the changing market trends and operate in good sync with customer-specific requirements by using high-end fillers, top-quality stabilizers, novel processing methods.

The most primary thing about the use of PP Filler Masterbatch is safety. The manufacturers avoid adding any harmful compounds like heavy metals, formaldehyde, and toxic substances to the product so that it is perfect for a whole range of industrial applications. Compliance with appropriate international safety standards (including REACH) ensures that the product is suitable for diverse applications.

PP Filler Masterbatch used in various industries examples to manufacture plastic bags, woven sacks and many other industrial packaging products,automotive components as well as household items etc. Outside of these individual applications, the product is readily modified to suit other industries using composite materials which may benefit from savings and better material properties as well.

Adding PP Filler Masterbatch to plastic by its nature during the pic havas process has benefits and savings from both processing point of view or cost reduction standpoint. The masterbatch can be incorporated depending on the plastic type and final product specifications e.g., injection molding, extrusion or film blowing.

Yes, it is crucial for the businesses to maintain high-standards with a product like PP Filler Masterbatch. The same manufacturers offer custom-made filler masterbatches to meet the specific needs of each customer with excellent support services for their clients. A comprehensive testing of the properties of masterbatches are carried out continually which enables a regular and controlled production to exceed these high quality standards.

Environmental Masterbatch is a tech-driven company integrates technology research and development, manufacturing, sales, and after-sales support. Month it produces of 5000 tonnes each utilizing 15 production lines. Our sales network covers over 60 countries and regions that cover different elements of China, Europe and America as well as the center East, Southeast Asia, Africa, India, and several other countries.

The Environmental Masterbatchis dedicated to the principle of service "Survive with quality, establish with full confidence". Our company is expert in providing customers integrated synthetic functional options along side speedy, safe and convenient logistic services. We offer a 24-hour hotline support after sales and solutions.

Main products: White/black/color pp filler masterbatchDesiccant Masterbtch CaCO3/Na2SO4/BaSO4 filler master batch, Flame Retardant master batch, Brightener master batch, also much more master batches. We offer customized solutions based on the client's requirements and gives free samples test. Create an order following tests are performing.

The use of advanced technology and equipment, such as automated machines, standardized procedures, and pp filler masterbatch designed by scientists assures the supply of top-quality products. The product is certified RoHS environmental certification, FDA certification, REACH certification, and SGS certification