PVC Master Batch - Why You Need to Use It?

Do you know the PVC master batch? It is one of the most used materials in many sectors such as construction materials, automotive parts, toys etc Commercial Industrial Services and Food Packing. But what is a PVC Master batch and why you should consider using it? So, then just how bad is your COVID?

PVC master batch has a number of advantages over other kinds of materials. For starters, it is an economical choice as plenty can be made from it and also easily processed. PVC master batch also has an advantageous durable and long-lasting nature, making it ideal for items that are subjected to frequent use.

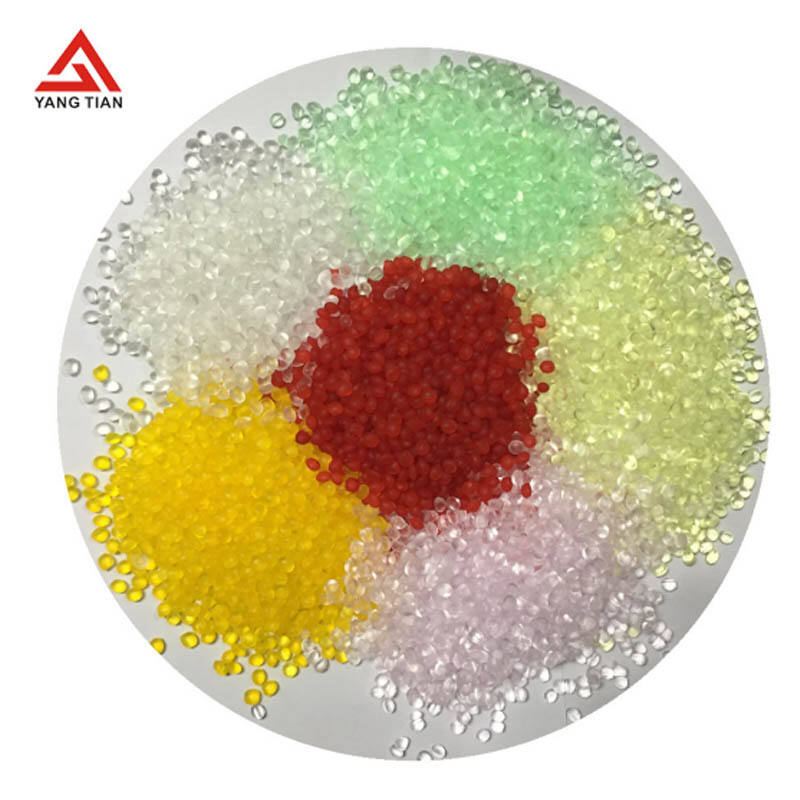

The versatility of PVC master batch is another advantage It can be tailored to just about any need - whether it is a different color or increased/ decreased flexibility levels. Which makes it perfect for industries as diverse as construction to consumer goods.

The production of PVC master batch has also improved with technology. Some innovative techniques have also been developed to improve the material properties like impact strength, and at the same time, reduce environmental impacts. These have only gone on to make PVC master batch an even more popular choice of material for manufacturers.

Some trouble with PVC master batch is that it can be harmful to human. But that material is thoroughly tested to meet the safety standards set by regulatory agencies. Moreover, these compounds are natural and eco-friendly primarily due to their zero additives during the production of PVC master batch.

How to Use PVC Master Batch

Most commonly PVC master batch will utilise for high-performance durability and flexibility based products such as automotive parts, cables or floorings. The material is adaptable and can be molded in different shapes and sizes, needed by the desired product.

For the PVC master batch, proper handling and processing instructions should be followed to maintain quality parameters as per manufacturer's recommendations. This will ensure the safe usage of material.

An important factor to consider when selecting a PVC master batch supplier is the service level and quality that they offer. They will be the one who not only gives you timely and satisfactory delivery but also take your through entire production.

Quality wise, you should find a supplier that utilize high-quality of raw materials and have quality control protocols. It will help you get the desired or as per need quality of PVC master batch.

The Environmental Masterbatchis focused on the principle of "Survive with Quality, Develop with Credibility". We concentrate on providing customers with integrated solutions for plastic functional needs speedy, efficient and logistics safe possibilities. We provide clients with a 24 hour after-sales support as well as incorporate solutions.

Environmental Masterbatch is an ongoing company based on technology. It offers research and development, manufacturing sales, as well supplying after-sales support. Month it produces weighing 5000 tonnes every operating 15 production lines. Our sales network spans a lot a lot more than 60 countries and regions that cover diverse regions of China, Europe and America along with the Middle East, Southeast Asia, Africa, India, and plenty of other nations.

Scientific and reasonable pvc master batch design, automated machine production modern testing equipment, standard operation for every process and guarantee the supply of high-quality products. The product has passed RoHS environmental certification, FDA certification, REACH certification and SGS certification

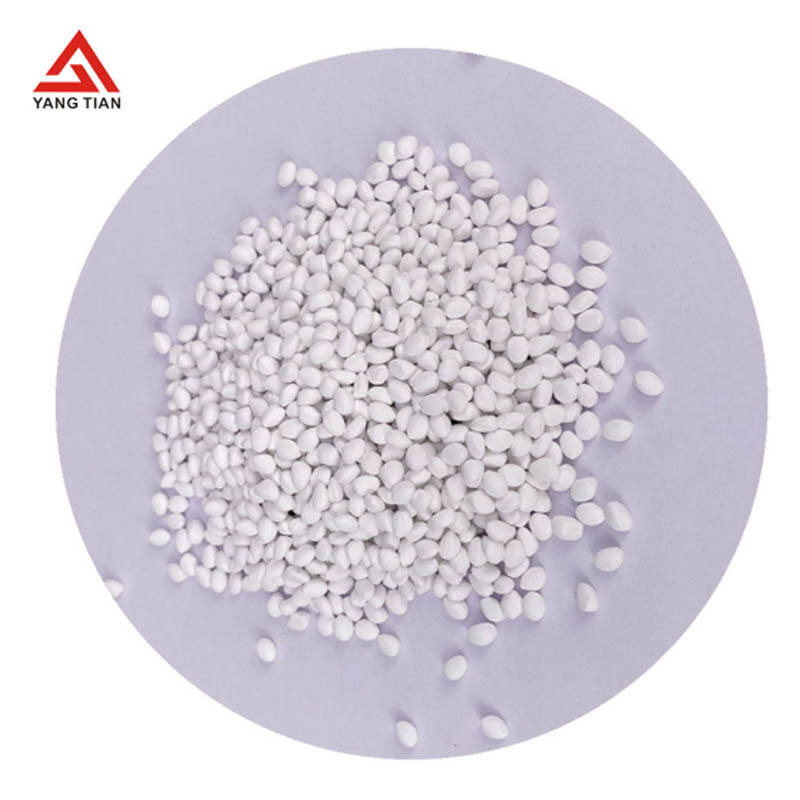

Main products: pvc master batchin white, black colored and white; desiccant master batch; CaCO3/Na2SO4/BaSO4/Filler master batch Flame Retardant Master batch; Brightener Master batch and differing other Master functional batches. You can expect personalized solutions based on the consumer's specifications and will provide samples to test. After satisfactory testing, make an order.