It is a specific type of plastic that we use for a number of products every day. HDPE is an acronym for High-Density Polyethylene. This name tells us that it is a strong plastic that is thicker than many other types of plastic. Workers use a process called polymerization to make HDPE. This means they take tiny pieces called ethylene molecules and combine them together, which forms this strong plastic. HDPE is a highly versatile material that is used in many items used in our everyday lives due to its strength and low cost.

That's why HDPE is widely popular in various sectors owing to its remarkable characteristics. HDPE is one of the strongest and most durable materials on earth. It gives it a long shelf-life without crumbling, making it perfect for shopping and storage products like plastic bags, crates, and containers. HDPE has an advantage of being light as well. Being light signifies that it is easily portable. Also, HDPE has a good ability of resisting the things such as water and chemical substances. This is crucial for HDPE since it enables safe usage of HDPE for the containment and transportation of hazardous materials that might endanger persons and the environment.

There are a lot of wonderful advantages of using HDPE in factories. First, HDPE is very versatile; it’s not overly expensive, and it can be used in several different applications. This allows factories to manufacture strong and as well as for durable products. The most unique thing about this plastic is that it can be used to make different products by melting it down and reshaping it. This fact provides this material with a superior flexibility that permits it to suit plenty of manufacturing process. HDPE is also recyclable, which is another key point. This means it can be recycled into new products, which is better for the environment. In doing so, factories can minimize waste and help save the planet by recycling HDPE.

HDPE is a cost-effective and practical solution for packing and storing products across industries. That strength makes it a great option for items that will be moved or stored for a while. Related to this is its lightness, which reduces transport costs, therefore helping businesses save money. Another benefit of HDPE is that it takes up less space when shipping. That way companies can move many products at the same time, which is more efficient. HDPE is also very simple to manufacture, and it can be adapted to specific needs, meaning factories can make bespoke packing solutions that fit their products perfectly.

Make sure you choose the proper type of HDPE for the project you have in mind. HDPE has many grades, and many uses. If you choose the wrong type, you could end up with a product that does not perform to its potential. Environmental Masterbatch has a range of HDPE grades that are applicable to almost all applications. They give you a hand in determining the right type of HDPE for your particular project, while you take key aspects like your product’s design, the required performance level, and budget accordingly. That way, you can make sure you are getting what you need.

Our Environmental Masterbatchis aimed at your principle "Survive through Quality, Create with Credibility" We focus on providing clients plus the complete solution plastics plus speedy, efficient and logistics safe services. Provide customers with a 24-hour support is after-sales and also provide options.

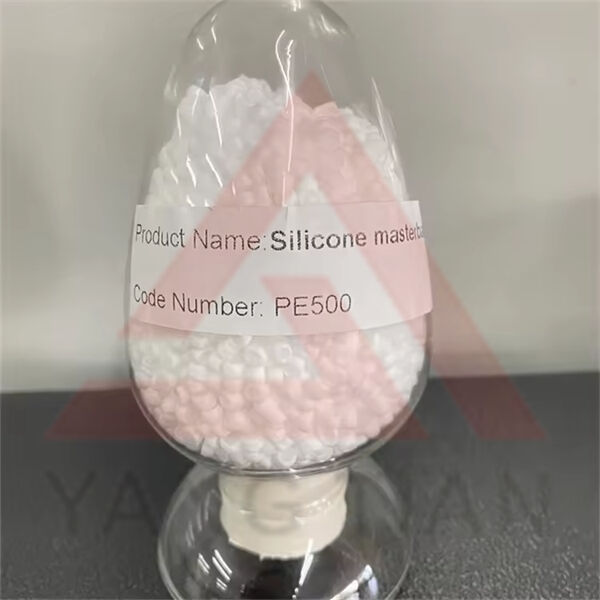

Main products: White/black/color raw material hdpeDesiccant Masterbtch CaCO3/Na2SO4/BaSO4 filler master batch, Flame Retardant master batch, Brightener master batch, also much more master batches. We offer customized solutions based on the client's requirements and gives free samples test. Create an order following tests are performing.

Scientific and reasonable raw material hdpe design, automated machine production modern testing equipment, standard operation for every process and guarantee the supply of high-quality products. The product has passed RoHS environmental certification, FDA certification, REACH certification and SGS certification

Environmental Masterbatch is a continuing business based on technology. It incorporates technology research and development also as sales, production and after-sales service. It produces weighing 5000 tonnes every on 15 production lines month. Our sales network spans a lot more than 60 countries, which include China, Europe, America, Southeast Asia and Africa.