Packaging also holds the prime place when it comes to safeguarding your materials from corrosion and damage. VCI (Volatile Corrosion Inhibitor) masterbatch - one of the topmost ways to boost up these materials outweighs.

VCI master batch is produced by mixing some specific proportion of plastic resins and anti-corrosive chemicals. This mixture produced a layer of protection that is able to reduce not prevent rusting process on the metal. Aside from being a tough coating, this has been an ultimate choice of packaging manufacturers around the world because it provides long-term protection.

Corrosion is a serious problem which might cost of loss for the economy. The National Association of Corrosion Engineers (NACE) International estimates that the global cost of corrosion is more than $2.5 trillion each year; It is therefore, hardly a shocker that VCI master batch has fast emerged as the number one choice for packaging manufacturers wanting to enhance service life and quality of their products.

VCI master batch work through the release of vapour molecules which cling to metal surfaces protecting from corrosion and thereby extending material life. This state-of-the-art technology to store products and transport them where fear of coral damage does not haunt anyone.

This is the reason behind multiple benefits of using VCI master batch, and this can be a most suitable solution for packaging manufacturers so as to increase life span of product without effecting environment. Following are some major benefits of using VCI Master Batch for the long-term life of products:

Reduced Product Damage: The VCI master batch removes the rust and other damages in storage or transportation hence reduce product damage.

Better Product Quality: The withstanding protection of VCI master batch allows higher level UR Wire India | Cable Technology News States That So as a part gets stored for outer market, it needs convincing features such that CAN and will help gain PULL-UP quicker.

Cost: Replacing corroded materials can be an expensive repair. Additionally, use of VCI master batch may decrease the necessity to replace materials which can save manufacturers costs.

Increase in Customer Satisfaction: By rectifying the quality of products and reducing damage slightly, packaging manufacturers can increase customer satisfaction to huge heights.

One major ecological issue is derived from the use of plastic. According to the United Nations Environmetal Programme (UNEP), 8 million tons of plastic waste finds its way into the oceans each year creating widespread environmental damage.

One way to conquer the problem of reducing plastic waste is via VCI master batch. VCI masterbatch is biodegradable and is not hard to use like other anti-corrosion coating does. Packaging manufacturers can start by combining VCI master batch with their packaging materials.

Corrosion can be possible in the electronic devices, machinery and vehicles which are key components. The corrosion damage can be expensive to repair, shortened life of the equipment and at worse a complete havoc.

One of the proven techniques to protect key components from corrosion damage is through using VCI master batch. VCI master batch: VCI master batch forms barrier and prevents rust and corrosion caused by it.

To sum up, VCI master batch is being used more and more by packaging manufacturers in a bid to improve the quality of their products as well extend their lifespan. The use of VCI master batch presents several advantages such as the improvement in product quality, a reduction in transit damage on finished goods which leads to overall cost saving and improved customer satisfaction.

In addition, VCI masterbatch serves as one of the most sustainable answers to today's environmental complication - plastic waste. Manufacturers may help to minimize the environmental impact of plastic waste by using VCI master batch integrated into packaging materials.

Finally, the benefits of VCI master batch can be seen not just in the packaging material alone. It provides comprehensive protection to vital parts such as equipment, electronics and vehicles against corrosion.

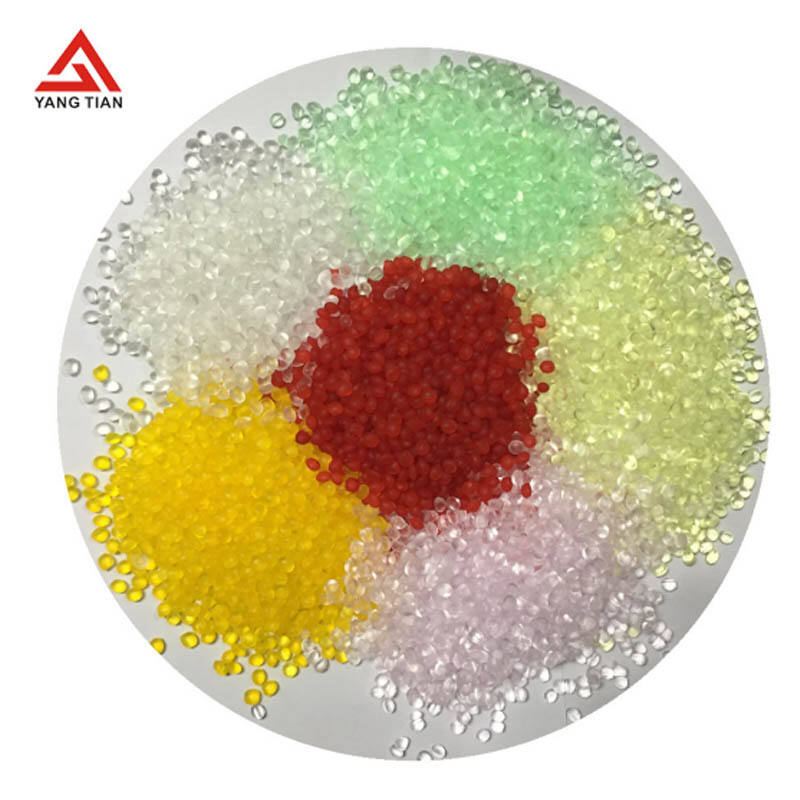

vci master batch design that is scientific and rational Automated machine production advanced testing equipment standardized operation for each process, guarantee to supply high-quality products. The product is certified by FDA, SGS, RoHS and REACH.

Our Environmental Masterbatchis targeted on the concept "Survive through Quality, build and Credibility" We focus on providing customers with integrated plastic functional solutions quick, easy, and logistics secure services. We have a 24/7 hotline for after-sales support and solutions.

Environmental Masterbatch A small centered business on technology, incorporates research and development, production and sales along with after-sales services. It produces that weigh 5000 tons each, on 15 production lines month. Our sales network spans more than 60 countries and regions that cover different elements of China, Europe and America as well as the Middle East, Southeast Asia, Africa, India, and lots of other nations.

Principal products: white/black/color vci master batchDesiccant master batch; CaCO3/Na2SO4/BaSO master batch Flame Retardant Master batch; Brightener Master batch and more Master batches for functional purposes. In line with the needs of customers We can offer custom-designed solutions free samples test. Spot an order after conducting tests.