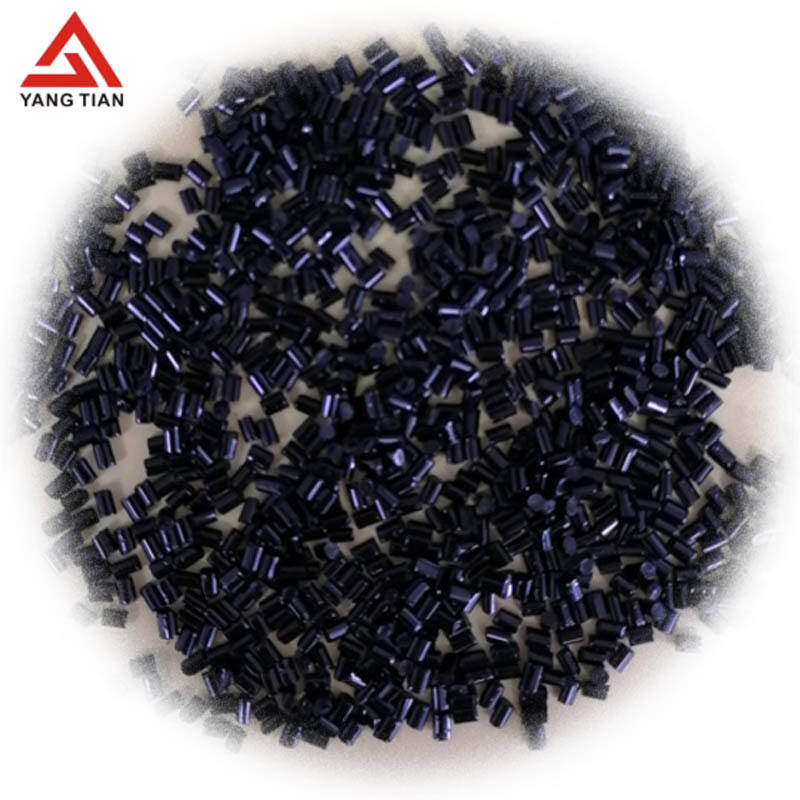

Black masterbatch is a critical component of countless products with its important additive feature in manufacturing various different plastic goods. First and foremost is a white pigment dispersion, which we use to create our own black tint (a rule in fine art inkjet pigments) that give deeper blacks than what can be achieved simply by diluting solvent or dye based stock. The emergence some leaders in Europe, Southeast Asia and the Americas sub-continents making them favorites amonst many industries across the globe are very few black masterbatch manufacturing companies. In addition to producing high quality batches, they are brilliant examples of how by having a better understanding for what each market requires - on both an international and domestic stage.

Why Our Black Masterbatch Manufacturers Lead Across All Markets

Versatility and adaptability are what distinguishes our manufacturers from the rest. Each region is a different, regulated market with its own distinct weather conditions and consumer preferences. An important driver is indeed European markets, and their emphasis on eco-friendly / REACH compliance. As a countermeasure, our suppliers devise eco-friendly formulas with recyclable ingredients that will limit the damage done to nature. Manufacturers as an alternative produced tougher, heat-resistant blends for the automotive and packaging sector - where American industries need high-performance masterbatches. One size clearly does not fit all, and these parameters shift again on a customized basis when we consider the fact that in Southeast Asia low costs prevail as against Africa where tough-climate performance is crucial. It is in meeting these varied demands with utmost precision that our manufacturers establish themselves as reliable partners across the globe.

It is hidden why We are established as one of the Chief Black Masterbatches Suppliers in Europe, America, Southeast Asia and Africa

Here it is all about a blend of innovation and control. Staying at the forefront of pigment technology and polymer science, we have made vast investments in research and development by our manufacturers. They use high-tech machinery to match the pigment and disperse it evenly throughout so that you get a consistent, vibrant color. Furthermore, robust quality controls ensure that every batch either matches or exceeds world standards. This commitment to quality strikes a chord with customers who are looking for the same reliability and stability in their supply chain due to which, our black masterbatches have been; one of the most trusted options globally.

International Solution Providers to Black Masterbatch: The Leaders Among Our Manufacturers

What differentiates our manufacturers is they can provide turnkey solutions, providing well beyond simple product. This include technical support for the customized products, application engineering services and troubleshooting throughout all phases of the product. This holistic model leads to enduring relationships and helps clients with tailored advice that solves their unique production problems. Furthermore, an extensive logistics network enables quick dispatches to even far-flung locations and minimizes downtime and increases operational efficiency for global customers. Such full-service model ensures them a competitive edge in overseas markets.

EU to Africa: Black Masterbatch in Regional Standards

It is also important to follow regional norms in order to be accepted globally. This involves stringent REACH regulations and demanding eco-labeling criteria of the EU market. To comply, manufacturers treat masterbatches to minimize their contribution to VOC emissions and also use sustainable raw materials. In the Americas they steer through FDA approvals for food-contact applications to protect the health of consumers. In response to the growing emphasis on recyclability in Southeast Asia, they introduce bio-based and readily-recyclable alternatives. On the other hand, in those African markets with a lot of exposure to sunlight and high humidity factors they have UV-stabilised formulations and anti-fungal specifications as priorities. This degree of detail is critical to maintaining 50-state compliance and customer satisfaction around the globe.

Satisfied Customers from all the World Love it

Another example comes from Maria in Spain: she thanks us for our environment-friendly black masterbatch, since we can finally offer a green alternative to one of the highest demanded raw materials faster than expected and with increased aesthetics.

USA: Robert from America appreciates our masterbatch production technology of Heat Resistant Black for Automotive Parts and the readiness to provide solutions by Technical Support Team.

Wei Ling (Malaysia) of Southeast Asia: She used Black Masterbatch and found BTP's product quality is good, yet competitively priced; this allows her to stay competitive in packaging industry.

Africa: Samuel from South Africa recently thanks for the Weather ability of our black masterbatch, which prolongs durability and lifespan of its outdoor products made on this continent -and that increased customer satisfaction.

With high technical knowledge, market awareness and will to be best in everything have helped the black masterbatch suppliers India create a special place for themselves at client as well end. Their expertise in custom solutions for each market has created the necessary conditions to achieve a global success and help them to be inevitable actors on all markets of international plastics industry.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BE

BE

MK

MK

AZ

AZ

JW

JW

LO

LO

MN

MN

SO

SO

MY

MY

UZ

UZ

XH

XH