Best Food Grade Black Masterbatch Manufacturers to Ensure Safe and Stable Pipe Production

The pipe industry is very important for mineral extraction through drilling, it provides water and gas pipelines as well as irrigation networks which are vital for everyday human needs. These are basic equipment without which our everyday undertaking would have been insignificant. The selection of the materials that are used in manufacturing plays an important part, as it can lead to positive or negative contributions towards pipes becoming high quality and reliable performing components. This is why many in the industry choose to use food grade black masterbatch when producing pipes. In this piece, we will discuss some of these benefits and matters to be considered while selecting the right kind of manufacturer for your food grade black masterbatch requirements in a pipe industry.

How Pipe Industry Experts Prefer Food Grade Black Masterbatch

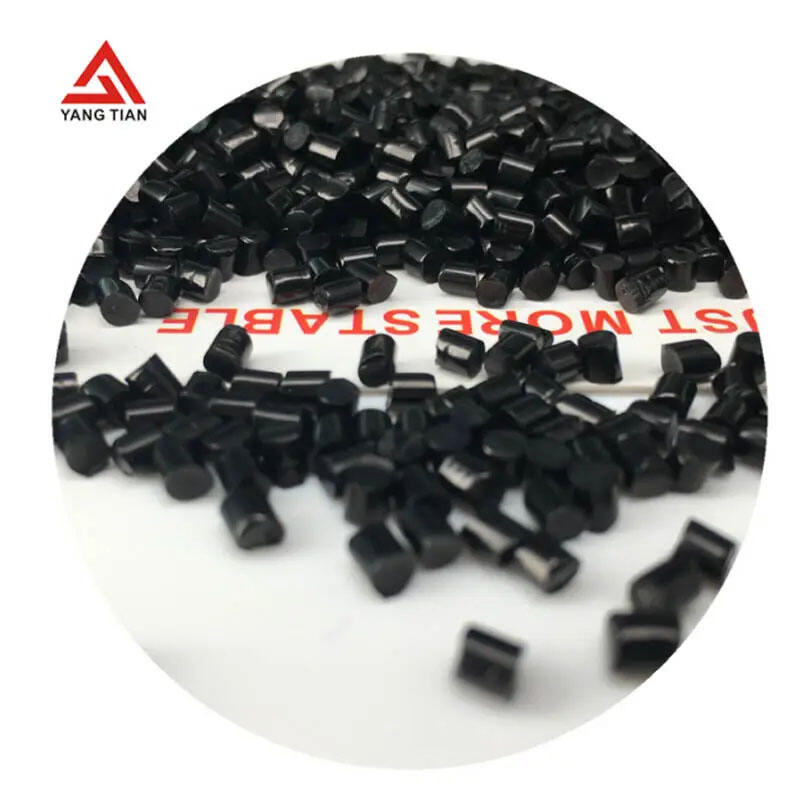

Food grade black masterbatch is a blister plastic proppant for pipe raw material processing, which includes color matching agent supply ability and improves opacity by dyeing the base resin. These additives are produced with the highest quality materials and in compliance with strict safety regulatory standards. The ability of food grade black masterbatches to comply with foods contact regulations is one of the most important reasons why they are so popular in pipe industry. This means that it is food safe and free from heavy metals as well as toxins. Furthermore, the food-grade black masterbatch has stronger advantages in the improvement of plastic materials properties. It helps plastics withstand outdoor conditions, including boosts to tensile strength, impact resistance and UV stability. In addition, it can also reduce the plastic shrinkage and warpage of products to improve their dimensional stability;

Food Grade Black Masterbatch Manufacturers

While you are behind the perfect food grade black masterbatch manufacturers who meet your pipe industry needs, consider plenty of factors. The first thing that you must do is verify whether the manufacturer from which you are planning to purchase have a good reputation and quality products. In general terms, it is very useful to read some reviews and testimonials from other customers so that with these data you can have a more reliable image of whether or not the manufacturer fulfills any type of product. In addition to this, it is also important for a manufactory evaluation of case the production capacity and manufacturing capabilities. Will they be able to satisfy the masterbatch volume you need in your time frame? Question 3: Do they have the technical experience and technological foundations to build your precise details required for the manufacture of piping? Geographical Location of The Manufacturer Being able to work with a local manufacturer is ideal when it comes to save on shipping costs and short lead times. Nonetheless, in cases where there is no appropriate local manufacturer available then searching for manufacturers who do international shipping as well starts making sense.

Benefits of Food Grade Black Masterbatch in Pipe Industry applications

There are several benefits to incorporating food grade black masterbatch in the making of pipes.

Improved Appearance - Pipe with food grade black masterbatch look more beautiful and identical. Such a thing can raise the beauty and aesthetics of them.

Greater Durability: Food grade black masterbatch raises the strength of plastic materials that increase compatibility with harsh effects (including tearing, UV radiation and weather. This makes them appropriate to be used in an outdoor setting

All of this ensures that food grade black masterbatch does not contain any harmful substances, making it a great option for almost all applications when the product will be in contact with food items. Incorporating a food grade black masterbatch will provide regulatory certainty and reduce the risk of product recall for liability outset.

Choosing Black Masterbatch Manufacturer in Food Grade Appropriate to Your Pipe Production Needs

These are some of the factors that should be kept in mind while selecting a food grade black masterbatch manufacturer which can help you produce.

Quality - Ensure that the company manufactures top-end food grade black masterbatches as per regulatory requirements and market standard.

Quantity - Choose a supplier that has capacity to deliver rubber masterbatches as per your quantity constraints within the period you set.

Skill set - Look for a manufacturer which possesses the skills and technological know-how needed to produce exact tower requirements that are vital when producing pipes.

Price Check: Make price comparisons with other retailers to guarantee a good deal for top-notch products. However, quality should not be sacrificed for the sake of reduced expenses.

Customer Service - opt for a manufacturer who has a positive reputation when it comes to after-sale customer service. This is to facilitate the quick and prompt redressal of any queries or problems.

In Conclusion

Using food grade black masterbatch in the process of producing pipes is crucial to maintaining secured and reliable products. A good status Brief production cycle Advanced technology Nearby location the price of food grade black masterbatch is different. Cooperation with a professional and experienced food grade black masterbatch supplier will ensure you are able to produce top quality products complying with all relevant regulations, while at the same time keeping your costs down ensuring highest profitability.

Table of Contents

- Best Food Grade Black Masterbatch Manufacturers to Ensure Safe and Stable Pipe Production

- How Pipe Industry Experts Prefer Food Grade Black Masterbatch

- Food Grade Black Masterbatch Manufacturers

- Benefits of Food Grade Black Masterbatch in Pipe Industry applications

- There are several benefits to incorporating food grade black masterbatch in the making of pipes.

- In Conclusion

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BE

BE

MK

MK

AZ

AZ

JW

JW

LO

LO

MN

MN

SO

SO

MY

MY

UZ

UZ

XH

XH