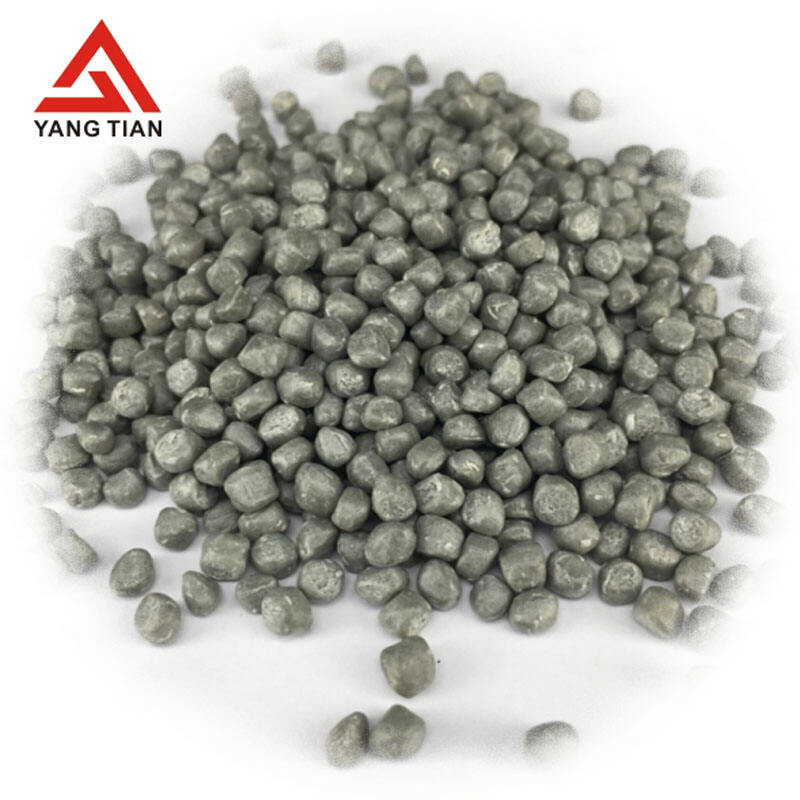

Filler brand is an excellent additive in order to improve the quality of materials.

This coating has grown in popularity as it helps strengthen and improve the cosmetic appeal of a wide range of products. The versatile material can enhance physical properties and improve the appearance of parts, whereas cryogenic deflashing is mainly employed in enhancing optical characteristics like transparency and color consistency. Using filler brand properly can dramatically improve the strength and beauty of plastic products, making it an important method in production.

The process of Filler brand making is highly demanding keeping in view the constant demand for Innovation & Industry Legislation which focuses on safety. The topmost filler brand manufacturers in the Philippines are the leading innovators when it comes to developing new and improved models of composite fillers. They focus not only on improving the performance and usability of their products but also on ensuring that they are achieved in the safest possible ways. Filler brand manufacturer Across industries deliver are committed good quality filler brand Maintain their focus on innovation and safety

Filler brand has a wide range of applications in the general industry, mainly used in plastic production. This has a broad applicability over multiple products including packaging materials, toys, appliances, automotive parts and construction supplies. The wide utilizing of filler brand over various divisions tells about its indispensable bit in the fabricating method for assorted industries. It is the key factor, which greatly shapes quality and provability of products at present.

At first sight, the processing of filler brand into plastic production has a very complicated composition process; however in practice it is rather simple and straightforward. The brand is mixed with the plastic material, generally during extrusion or injection molding steps. The above will depend on desired end product characteristics and properties. Carefully follow the instructions laid down by the producer is vital as this will make it far less likely that filler brand would be properly used, ensuring you plastic product performance and top-quality upgrades.

These pillars are quality and service, the 2 key considerations to check before finding a filler brand manufacturer. Filler brand manufacturers in the Philippines provide a quality assurance to their product line as they offer reliability and consistency. In addition, these manufacturers are known for providing outstanding customer service and after sales technical support that helps in making a strong place among-st the top suppliers of plastic manufacturing industry. Customers can count on it these manufacturers for quality with full support of their product all the way through every stage of its development.

All in all, the leading filler brand manufacturers in the Philippines shine with their undying ambition for quality and safety excellence. Circularize has a broad product portfolio to serve the specific requirement in different sectors, making their systems very adaptable and flexible for industries. In focusing on customer satisfaction and maintaining adherence to industry standards, these manufacturers are able instill trust in entrepreneurs who can be assured of the ongoing support they will receive along with interest-class products for their plastic manufacturing needs. Meanwhile, dedication to quality products and global market standards makes them powerful agents in the filler brand domain.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BE

BE

MK

MK

AZ

AZ

JW

JW

LO

LO

MN

MN

SO

SO

MY

MY

UZ

UZ

XH

XH