HDPE, or high density polyethylene, is a strong and multifunctional type of plastic. This special plastic is made from oil, a natural resource that comes from the ground. One of my favorite things about HDPE is that it can be melted down and re-formed into a wide variety of other products. HDPE is highly common from all sorts of items surrounding you. This type of plastic is used for things like milk jugs, shampoo bottles, and some types of playground equipment. HDPE is very strong, and many prefer it for a wide range of applications.

Because of HDPE's extreme strength and longevity many factories and companies enjoy using it. This material is also resistant to potent chemicals, so it won’t get ruined when it comes in contact with stuff, like cleaning products. Furthermore, HDPE cannot break down in sunlight, making it an excellent option to be used for outdoor products. It is also lightweight, which makes it easy to move and shape. This moldable versatility can contribute to communications systems, electrical devices and sensors that may be required by different industries.

HDPE is commonly used in packaging, construction, and pipe manufacturing. It also subsumes a vital part of our involvement in producing our range of Environmental Masterbatch products. These products are unique because they enable industries to lead the way in developing more environmentally sensitive materials. They accomplish this by sourcing recycled materials and reducing waste in the manufacturing process. So, basically, not only does HDPE go on to become useful products, it also goes a long way toward protecting our planet.

HDPE has the benefit of being recyclable. What is recycling? Recycling is a very important process because that allows us to instead of throwing things away and making more and more landfills we can make them into new items. The good news is that HDPE is one of the most widely recyclable plastics. Recycled HDPE can be used to create a range of new products. This helps lessen waste and conserve natural resources, something we all need to be more aware of.

Compared to wood and other materials, it is also more environmentally friendly when using HDPE. When we use wood to make products it often means trees need to be felled which can be bad for forest and wildlife. You can help alleviate that impact on our environment, and conserve valuable natural resources, by choosing HDPE for products such as outdoor furniture. It's an important if incremental move in ensuring we take care of our planet for generations to come.

It is really interesting the way HDPE is manufactured. It is made by linking small pieces together, known as ethylene molecules. When these small molecules are linked, they form long chains that give the plastic strength. This is a process known as polymerization. As a result, HDPE is resistant to high temperatures and many different types of chemicals. This makes it ideal for outdoor use, where it will be directly exposed to sunlight and weather.

You probably have HDPE in many of your household products, including milk jugs, shampoo bottles and trash bags. It is also used to manufacture tubes for transporting water and gas. This means that it does not decompose so it lasts a long time which is why it is used for such applications. HDPE is also very beneficial for environmental projects. It’s commonly used for liners in landfills and systems that treat wastewater, because it has a long lifespan and can withstand chemicals.

The use of advanced technology and equipment, such as automated machines, standardized procedures, and high density polyethylene material designed by scientists assures the supply of top-quality products. The product is certified RoHS environmental certification, FDA certification, REACH certification, and SGS certification

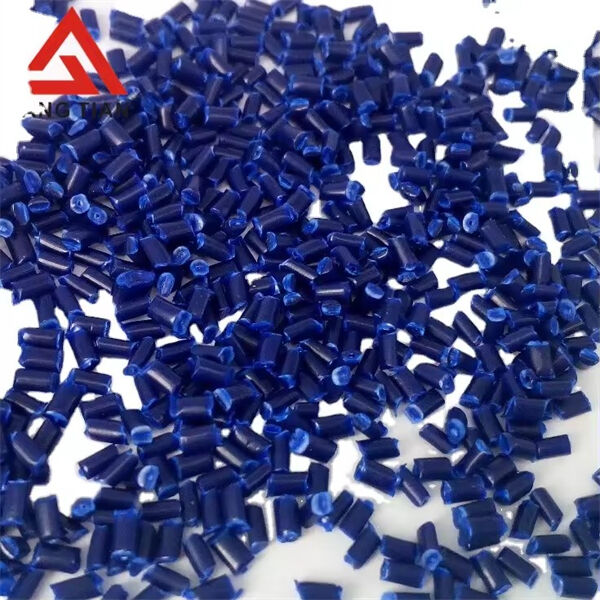

Main products: White/black/color high density polyethylene materialDesiccant Masterbtch CaCO3/Na2SO4/BaSO4 filler master batch, Flame Retardant master batch, Brightener master batch, since well as more master batches. You can expect modified solutions based on customer requirements and gives free samples try. Setting an order after conducting tests.

The Environmental Masterbatchis dedicated to the principle of service "Survive with quality, establish with full confidence". Our company is expert in providing customers integrated synthetic functional options along side speedy, safe and convenient logistic services. We offer a 24-hour hotline support after sales and solutions.

Environmental Masterbatch A small centered business on technology, incorporates research and development, production and sales along with after-sales services. It produces that weigh 5000 tons each, on 15 production lines month. Our sales network spans more than 60 countries and regions that cover different elements of China, Europe and America as well as the Middle East, Southeast Asia, Africa, India, and lots of other nations.