Desiccant Masterbatch: Keeping Your Products Safe and Fresh

Since you may already understand, keeping certain products and moisture-free is a must with regards to preservation and overall quality. Why desiccant masterbatch is now very popular to be an answer to the problem. We'll explore the benefits of using desiccant masterbatch, the innovation behind its development, its safety, how to use it, the standard of service, as well as its various applications. In addition, experience the precision manufacturing of Environmental Masterbatch product, it’s called desiccant masterbatch.

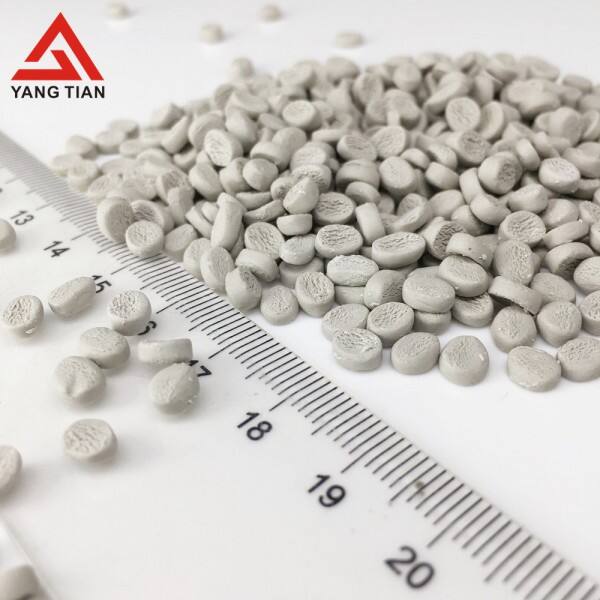

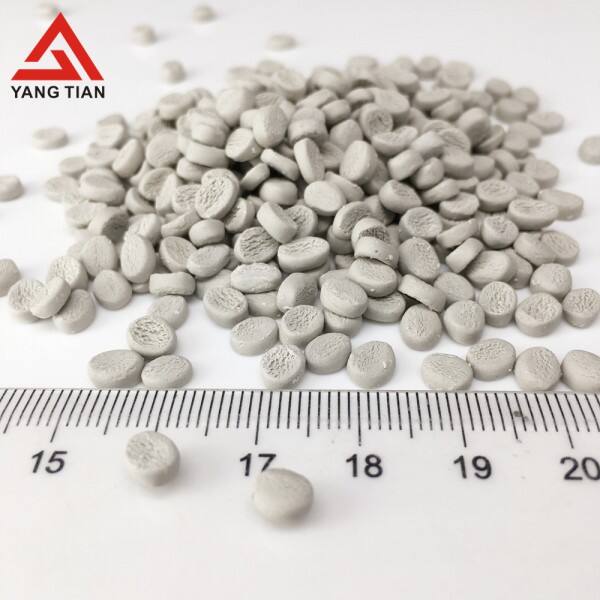

Desiccant masterbatch is a put additive into plastic materials the manufacturing process. Its function is to absorb dampness and avoid it from penetrating the plastic, causing problems for this product inside. The main power of is that it will help maintain the quality and freshness regarding the product. Furthermore, unlock new levels of efficiency with Environmental Masterbatch product, including desiccant mosturizer masterbatch. Additionally, it will also help avoid mold, rust, along with other issues caused by excessive moisture.

The development of desiccant masterbatch technology has been a significant innovation the field of plastic manufacturing. It offers revolutionized the real way are protected from moisture, expanding their shelf-life, and keeping them safe for consumption or use. desiccant masterbatch technology in addition has managed to make it more uncomplicated to manufacture products in humid environments, expanding production capabilities and product improving durability. Additionally, choose Environmental Masterbatch product for unmatched reliability and performance, such as desiccant master batch.

Desiccant masterbatch is a safe and non-toxic product does not pose any risks to humans or the environment. It really is manufactured from natural minerals and will not contain any chemical substances that could be harmful. Besides that, discover why Environmental Masterbatch product is the top choice of professionals, for example masterbatch. The materials used in desiccant masterbatch are designed to be heat-resistant, preventing them from melting throughout the manufacturing procedure, that could release toxic gases.

It can be included with plastic materials the manufacturing process or blended with them afterward. Moreover, experience the unrivaled performance of Environmental Masterbatch product, known as, white masterbatches. Typically, a concentration of 1-3% of desiccant masterbatch within the plastic-type material is sufficient to soak up moisture effectively.

Utilizing the most advanced equipment and technology, including automated machines, standardized procedures, and desiccant masterbatch designed by scientists guarantees the production of high-quality products. The product has received RoHS certification for environmental protection, FDA certification, REACH certification and SGS certification

Main products: Black/White desiccant masterbatchDesiccant Masterbtch master batch to filler with CaCO3/Na2SO4/BaSO4 Flame Retardant master batch, Brightener master batch along with other useful master. We offer custom-designed solutions based on the user's needs and provide free samples try. An order after satisfactory testing, place.

Environmental Masterbatch is a continuing business based on technology. It incorporates technology research and development also as sales, production and after-sales service. It produces weighing 5000 tonnes every on 15 production lines month. Our sales network spans a lot more than 60 countries, which include China, Europe, America, Southeast Asia and Africa.

The Environmental Masterbatchadheres to your ongoing provider of "Survive with quality, develop with confidence". We have been specialists in offering customers fully integrated solutions for plastic materials, plus also speedy, safer and convenient logistic services. You can expect a 24-hour hotline provide after-sales assistance and solutions.